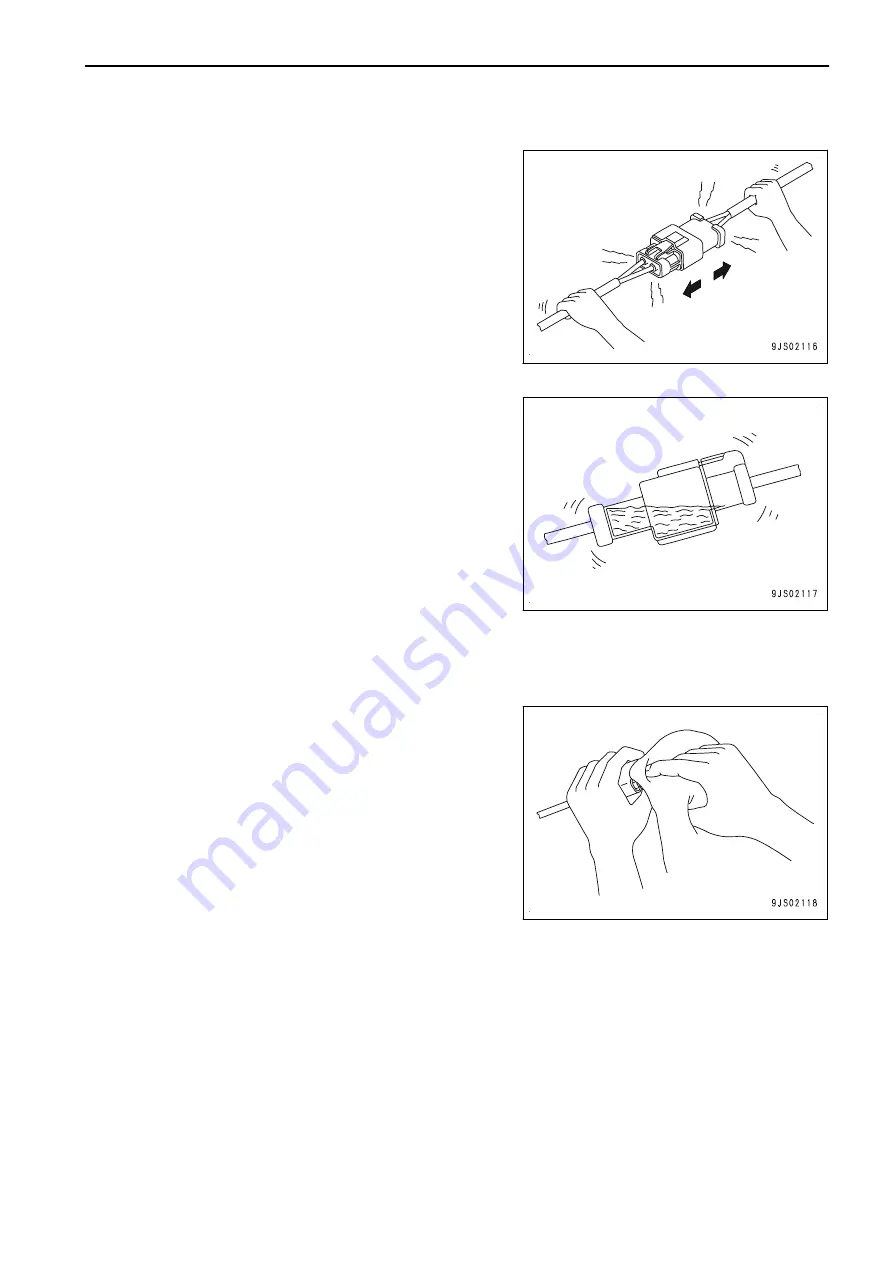

Disconnection in wiring

If the wiring harness is pulled to disconnect the connector, or

the components are lifted with a crane while the wiring harness

is still connected, or a heavy object hits the wiring harness, it

may separate the crimping of the connector, or damage the sol-

dering, or break the wiring harness.

Water entering the connector by high-pressure jetting

The connector is designed to make it difficult for water to enter

(drip-proof structure), but if high-pressure water is sprayed di-

rectly on the connector, water may enter the connector, de-

pending on the direction of the water jet.

Do not spray water directly on the connector.

If the connector is waterproof, intruded water is hardly drained.

Once water enters into the connector, water goes through pins

to cause short-circuit. Drying the drenched connector or take

appropriate actions before providing electricity.

Entry of water, dirt, or dust when disconnecting a con-

nector

If any water, mud or dust is stuck to the outside surface of a connector, it can enter inside the connector when

the connector is disconnected. Before disconnecting the connector, wipe off any stuck water or dirt by using a

dry cloth or blow it with compressed air.

Oil, mud, or dust stuck to connector

If any oil or grease is stuck to the connector and an oil film is

formed on the mating surface of the male and female pins, the

oil prevents electricity from passing through resulting in defec-

tive contact. If any oil, grease, dirt or dust is stuck to the con-

nector, wipe it off with a dry cloth or blow it with compressed air,

and wash it with electrical contact restorer.

NOTICE

• When wiping the jointed portion of the connector, do

not apply excessive force or deform the pins.

• If there is oil or water in the compressed air, it causes

the contacts to become dirtier. Use clean air which any

oil and water has been removed from.

00 INDEX AND FOREWORD

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT

PC290LL-11

00-51