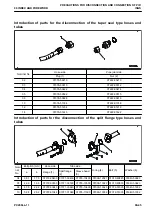

Introduction of parts for the removal of taper pipe thread type joint

Nominal No.

Nominal

thread size

Plug (1)

Square head type (A)

Hexagonal socket head (B)

01

R

1

/

8

07042-00108

07043-00108

02

R

1

/

4

07042-00211

07043-00211

03

R

3

/

8

07042-00312

07043-00312

04

R

1

/

2

07042-00415

07043-00415

06

R

3

/

4

07042-00617

07043-00617

10

R1

07042-01019

07043-01019

12

R1

1

/

4

07042-01222

07043-01222

14

R1

1

/

2

07042-01422

07043-01422

20

R2

07042-02026

07043-02026

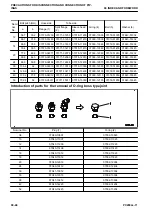

Precautions for installation and assembling work

• Tighten the bolts and nuts (sleeve nuts) to the specified torque (KES) unless otherwise specified.

• Install the hoses without twist and interference. If there is any in-between clamp, securely fasten it.

• Replace all of the gaskets, O-rings, cotter pins, and lock plates with new ones.

• Bend the cotter pins and lock plates securely.

• When applying adhesive, clean and degrease the surface to apply, and apply 2 to 3 drops of adhesive to

the threaded portion.

• When applying liquid gasket, clean and degrease the surface, and apply it uniformly after making sure that

the surface is free from dust or damage.

• Clean all of the parts. If there is any damage, dents, burrs, or rust found on them, repair it.

• Apply engine oil to the rotating parts and sliding surface.

• Apply molybdenum disulfide lubricant (LM-P) to the surfaces of the press-fitting parts.

• After installing the snap ring, check that the snap ring is settled in the ring groove completely.

• When connecting wiring harness connectors, clean the connectors to remove oil, dust, or water, then con-

nect them securely.

• Use the eye bolts without fatigue and deformation and screw them in securely. Match the directions of the

eyes and the hook.

• When installing split flanges, tighten the bolts uniformly and alternately to prevent uneven tightening.

• As a rule, apply liquid gasket (LG-5) or liquid sealant (LS-2) to the threaded portion of each taper male

screws which receive pressure.

00 INDEX AND FOREWORD

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIP-

INGS

PC290LL-11

00-47