AUTO PICLE-S

14

3.2

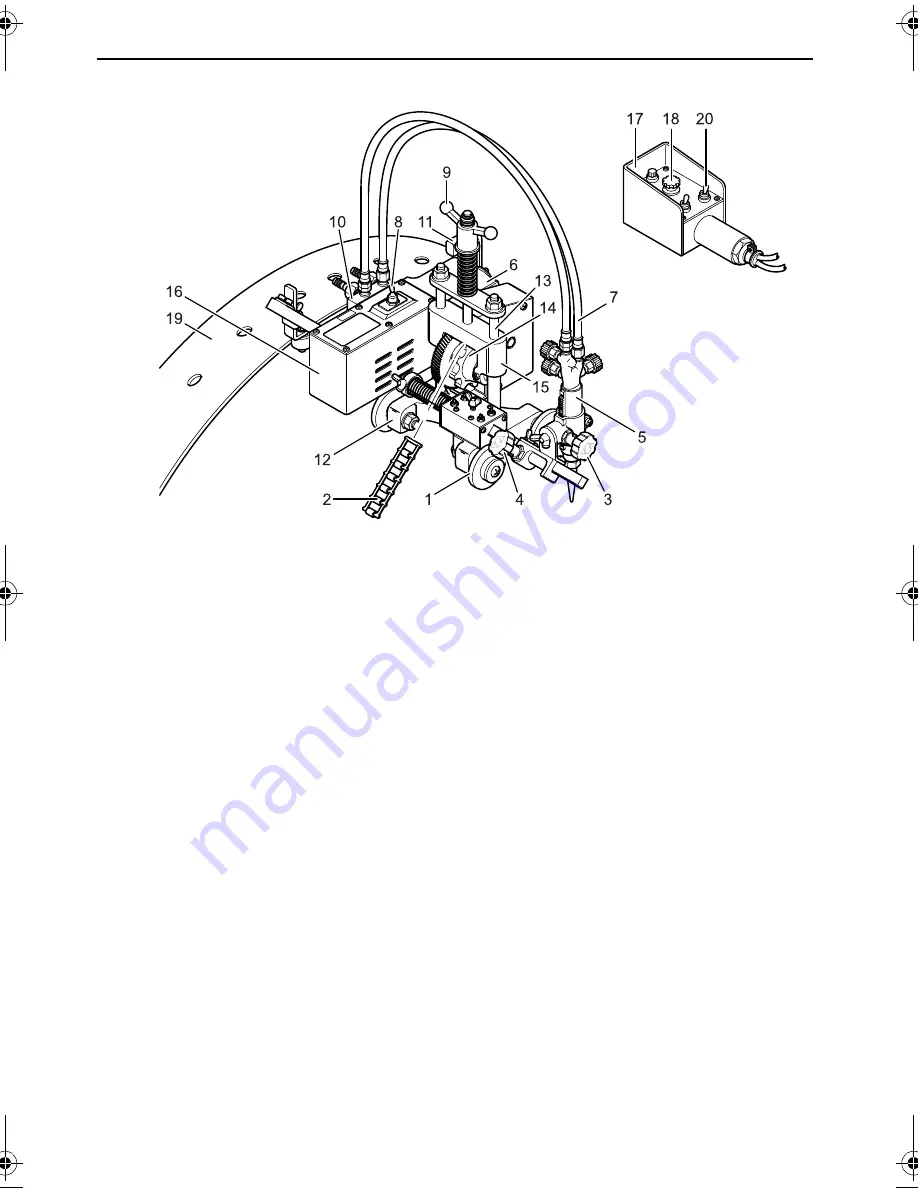

Name and function of each section

1. Wheel

Four wheels permit the machine to

run stable on pipes.

2. Chain

The machine attached to the rail

runs along the chain.

3. Torch up/down handle

Changes the torch height.

4. Cross-feed handle

Changes the horizontal position of

the torch.

5. Torch

Cutting thickness: 5~50 mm.

6. Gear box

Voltage control by means of a

speed-controlling resistor permits

staples speed change.

7. Hose

Installed between the gas

distributor and the torch. Two hoses

for oxygen and gas are combined

as a set.

8. Motor switch

Power switch for the motor.

9. Tightening handle

Tightens the handle to secure the

machine and pipes.

10. Gas distributor

Division into preheating oxygen,

preheating gas and cutting oxygen.

11. Clutch lever

Used to run the machine.

12. Main unit

13. Shaft column

14. Sprocket

15. Slide bracket

16. Motor

15 W; 5000 r.p.m.

17. Control box

Permits remote control.

18. Speed control knob

For controlling the cutting speed

from 100 to 700 mm/min.

19. Guide rail

There are four kinds of rails for

respective effective pipe cutting

diameters.

20. Directional changeover switch

For switching forward and

backward travelling.

Auto Picle-S.book Page 14 Thursday, April 11, 2002 11:15 AM

Summary of Contents for AUTO PICLE-S

Page 1: ...AUTO PICLE S REMOTE CONTROL GAS MOTORIZED PIPE CUTTING MACHINE KOIKE SANSO KOGYO CO LTD...

Page 11: ...AUTO PICLE S 10...

Page 13: ...AUTO PICLE S 12...

Page 25: ...AUTO PICLE S 24...

Page 31: ...AUTO PICLE S 30...

Page 37: ...AUTO PICLE S 36...

Page 39: ...AUTO PICLE S 38 8 2 Assembly drawing figure 8 2...

Page 40: ...AUTO PICLE S 39 9 Parts list 9 1 Body unit...

Page 43: ...AUTO PICLE S 42 9 2 Driving unit...

Page 46: ...AUTO PICLE S 45 9 3 Electrical and gas unit...

Page 49: ...AUTO PICLE S 48 9 4 Guide rail...

Page 51: ...AUTO PICLE S 50...