3: Installation

38

TS_619_00 PW9000DPA S2 User Manual 13/3/17

3.5.4 Connecting the battery cables

DC cabling for the battery system(s) must be completed by an Uninterruptible Power Supplies Ltd. engineer or one of its

approved service agents.

3.6

Customer Interface Board

The customer interface board is described in paragraph 2.5 with some of its common applications described in detail in

paragraph 7.2. This section deals with the connection of the dry port interface connections taken to terminal blocks X1 -

X4 which may be connected at this stage of the installation procedure.

All the on-board relays connected to these terminal blocks are rated at 60VAC / 8A and the Phoenix terminals can accept

cables of 0.5 mm².

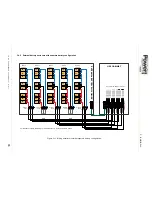

3.6.1 Customer dry-port interface terminal block – X1

X1 is a Phoenix spring terminal block and external connections should be made using s 0.5mm² cable.

Note that the ‘Remote Shut down’, ‘On-Generator’ and ‘Customer defined’ connections are described in Chapter 7.

Figure 3.13 Customer interface input connections (X1)

CAUTION: The customer interface board contain several DIP switches and jumper links which must be

configured by the commissioning engineer. Once set, DO NOT touch.

Key Point:

When the UPS cabinet is installed as part of a parallel system the customer interface board I/O is

disabled in the ‘slave’ cabinets if the system ‘Multidrop’ application is enabled. Under such circumstances the

required interface connections should be made to the board fitted in the ‘master’ module only.

Term

Contact

Signal

Function

X1/1

+3.3Vdc

Remote Shut down

(Do not remove the factory mounted bridge until external Remote Shut down is connected)

X1/2

GND

X1/3

+3.3Vdc

Generator Operation

(NC = Generator ON)

X1/4

GND

X1/5

+3.3Vdc

Customer IN 1

(Customer defined)

X1/6

GND

X1/7

+3.3Vdc

Customer IN 2

(Customer defined)

X1/8

GND

X1/9

+3.3Vdc

Battery temperature sensor

(If connected, the battery charger current depends on battery temperature)

X1/10

GND