Page 9

Version 01-2009

G

ENERAL SAFETY NOTES

S500K

1.5

Hazard sources

The

-2-wheel tractor may be used on commercial and well as private plots.

•

Before every start-up, check the machine for traffic and operational safety!

•

In addition to the information in this operator manual, observe the general safety and acci-

dent prevention directives!

•

During usage of the

-2-wheel tractor on public traffic routes (streets) the directives of

the street traffic ordinance apply in its most recent version. (For this also see 1.6)

•

Before beginning work, you must be familiar with all equipment and actuating elements

and their functions. Make certain that all protective devices are properly installed!

•

The user is responsible to third parties in the work area!

•

Standing in the work and hazard zones of the

-2-wheel tractor is prohibited!

•

Before starting to drive, check the surrounding area - children! Ensure sufficient visibility!

•

Do not let engine run in closed rooms!

•

The driver's clothing should be close-fitting. Avoid wearing loose clothing. Wear firm

shoes!

•

Caution is recommended when working with fuel - increased risk of fire! Never refuel in

the vicinity of open flames, ignitable sparks and hot engine parts. Do not smoke when fuel-

ing!

•

Before fueling, switch off the engine and pull out the ignition key (if present). Do not refuel

in closed rooms. Do not spill fuel! Use suitable filling aids.

•

To avoid risk of fire, keep the main engine clean!

•

Before maintenance and cleaning work, turn off the engine and remove the spark plug

connector!

•

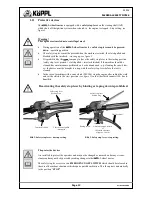

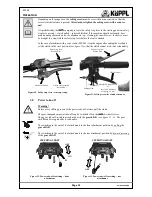

When coupling and decoupling tool attachments to or from the main engine, particu-

lar caution is necessary!

•

Make certain that all protective devices are properly installed!

1.6

Lighting devices on single-axle tractors

Here one must differentiate whether the one axled tractor

•

is guided by a pedestrian on the shafts,

•

is driven from a seat cart (single-track trailer) or

•

driven from a trailer.

One axled tractors, which are guided by a pedestrian on the shafts, require during darkness - or

when the weather requires – at least one simple lamp with white light, which should be attached

to the left side or carried along manually, so that the light is well visible to oncoming and pass-

ing traffic (§ 50 Para. 2 of the Road traffic act and § 17 Para. 5 of the Road traffic act).

One axled tractors which are driven from a seat cart or a trailer

•

must be equipped up to a width of 1000 mm with one headlight,

•

beyond a width of 1000 mm with two headlights

, which when pulling a one axled trailer can be fastened to this (§ 50 Para. 2 of the Road traffic

act).

If the one axled tractor is driven from a single-track seat cart, then a triangular reflector and a

taillight must be attached (§ 53 Para. 6 of the Road traffic act), blinking lights (travel direction

indicator) are not required for a seat cart. (§ 54 Para. 5 No. 5 of the Road traffic act).

For one axled tensile or work machines, which are operated by a walk-behind person, no operat-

ing permit or driver's license is required.

During transport of a one axled tractor with trailer on public streets, which is used for lof pur-

poses, the operating permit is sufficient up to a design-related maximum speed of 20 km/h. It