0901177 Rev: A (10/15)

Page 5 of 12

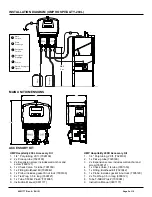

ELECTRICAL

Turn off all power before wiring the control. Check

with a voltmeter to ensure power is off.

Main Power Connection

One step-down transformer is provided with the UMP

control. Connect the high voltage side, through a switch

or circuit breaker in close proximity to the equipment

and marked UMP, to any 115/208/230 VAC power

source that is “on” when the dishmachine is “on” (i.e.

mains switch on dishmachine).

NOTE: The transformer provides power to both the

detergent and rinse circuits. The UMP will only operate

detergent or rinse when electrically signaled.

To wire main power connection:

(1) Check the voltage of the main power source and

make sure that it matches one of the three available

input voltages (115/208/230 VAC) of the

transformer inside the Ultra Micro-Pro.

(2) Remove all power from the dishwasher.

(3) Connect leads from the main power source to the

appropriate wires on the transformer.

* CAUTION: The UMP unit has high voltage connected

to the transformer. Always disconnect main power when

servicing the unit.

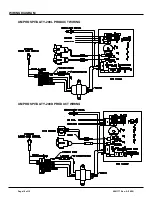

Remote Alarm

A remote 3 - 28 VDC alarm may be wired to the “alarm”

terminals on the circuit board. See wiring diagram on

page 10.

Pressure Switch Kit

For applications that do not have a dedicated rinse

signal from the dishwasher, the pressure switch can be

used to create a rinse signal using the transformer in the

unit (see wiring diagram for further details).

(1) Remove power from the dishmachine. Ensure that

power is removed from the dispenser.

(2) Locate the rinse injection fitting presently installed

on the dishmachine (if applicable). Near the

injection point, drill a hole for the pressure switch.

Drill the hole using a 11/32" bit and tap to 1/8" NPT.

(3) Wrap the threads of the pressure switch with 3 - 4

turns of plumbing tape, then install the pressure

switch into the drilled/tapped hole.

(4) Wire the pressure switch per the appropriate wiring

diagram on page 10.

Detergent Power Signal

A detergent power signal is required to activate the

detergent probe sensing or probeless initial charge. The

detergent signal can be jumpered from main power for

applications where the main power is controlled by the

on/off state of the dishmachine.

(1) Check the dishwasher for a power source that is

active during the washcycle only (example: the

magnetic contactor that controls the washpump

motor) and verify voltage. The Ultra Micro-Pro

circuit board will accept a detergent power signal of

14 - 240 VAC.

(2) Remove all power from the dishwasher.

(3) Connect leads from the detergent signal power

source to the detergent signal terminals on the

circuit board. Detergent signal must be the same

voltage as Rinse signal.

Rinse Power Signal

In addition to running the rinse pump, the rinse power

signal also triggers the detergent “recharge” injection if

probeless mode is selected

(1) Check the dishwasher for a power source that is

active during the rinse cycle only (example: the

rinse solenoid or rinse cycle light) and verify

voltage. The Ultra Micro-Pro circuit board will

accept a signal of 14 - 240 VAC.

(2) Remove all power from the dishwasher.

(3) Connect leads from rinse signal source to the rinse

signal terminals on the circuit board. Rinse signal

must be the same voltage as Detergent signal.

Conductive Probe Installation (if used)

(1) Install the probe in the wash tank below the water

level. It should be away from incoming water

supplies, near the recirculating pump intake, and 3

to 4 inches from corners, heating elements, or the

bottom of the tank. If an existing mounting hole

cannot be located, use of a 7/8" hole saw or punch

may be desired.

(2) Connect leads from the terminals on the probe to

the terminals marked “PROBE” on the circuit board.

(3) For best results, use 18 AWG multi-stranded

copper wire for the probe connection. Avoid running

the wire near high voltage AC lines.

ELECTRICAL