35

7.10 Coolant unit

In the USK 160 S, the coolant is supplied through

continuous circulation around the grinding wheel

using a submersible pump (7-14/1).

The abrasives are not immersed in water while the

machine is idle. The grinding sludge is collected in

the water tray.

The submersible pump is driven by the motor via a

circular belt.

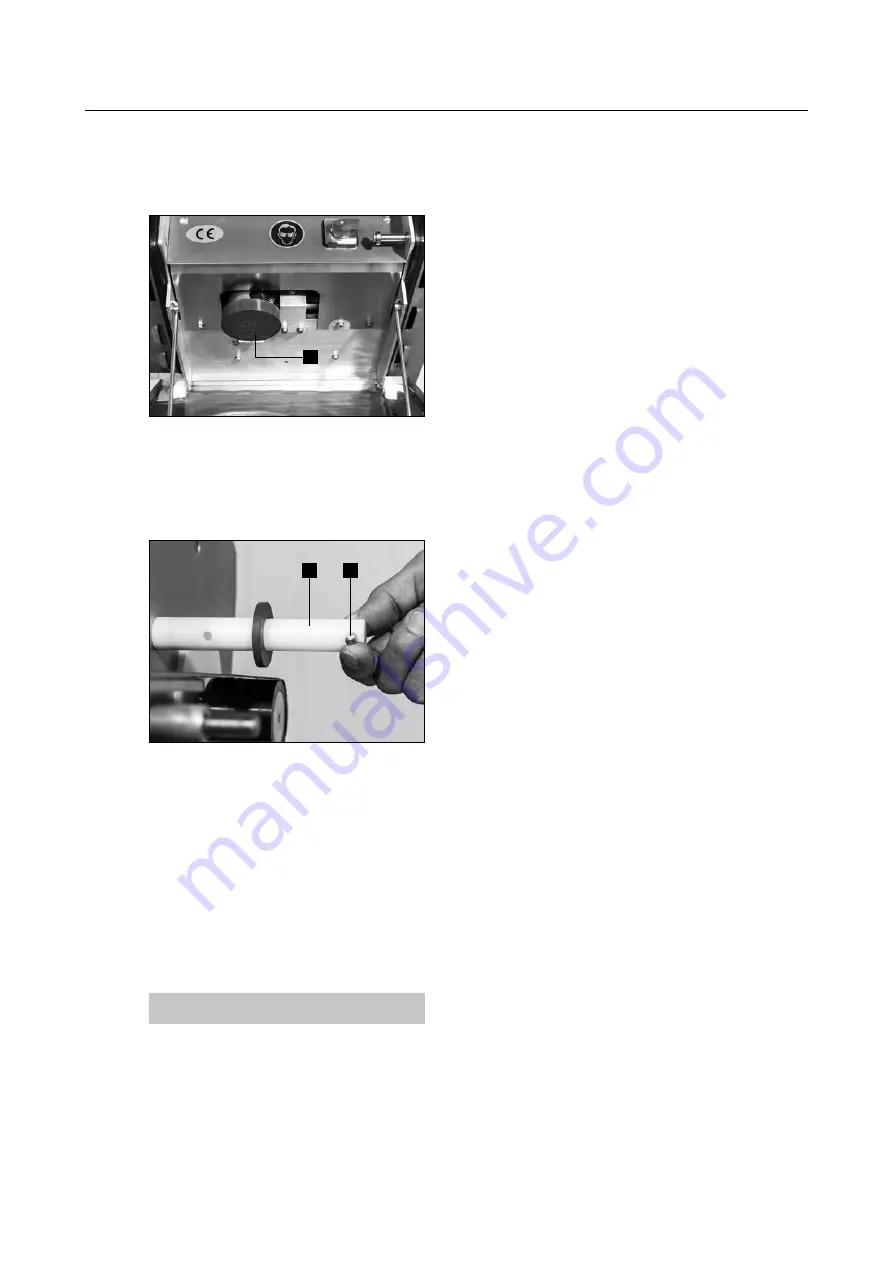

7.10.1 Belt cooling

The submersible pump feeds the coolant through

the water nozzle to the wet-grinding belt.

Coolant is apportioned by the swiveling of the

water nozzle.

In doing so, the flow rate of the coolant does not

change, rather the impact angle on the grinding

belt.

The pin (7-15/1) on the water nozzle (7-15/2) indi-

cates the angle at which the coolant will hit.

The standard setting is perpendicularly down-

wards.

Turning clockwise = more coolant

Turning counterclockwise = less coolant

For cleaning, the water nozzle is simply pulled out

after removing the protection hood.

NOTICE

Opposed to the belt side, for which as much

coolant should be applied to the wet-grind-

ing belt, the finned grinding wheel or serra-

tion grinding wheel must receive more subtle

doses.

7. Operation

Figure 7-14

Submersible pump

Figure 7-15

Adjusting the water nozzle

1

2

1

Summary of Contents for USK 160 S

Page 2: ...2 ...