PWR

KMB systems

The insulation voltage and the certified overvoltage class are not sufficient for the required overvoltage

category. This concerns the isolation of the power circuit compared to the output terminals (DC output

voltage, external backup source and signalling).

Additional measures:

The input voltage of the power module is limited to 300V CAT II with an additional voltage limiter while the

device is operated in a 300V CAT IV environment.

The voltage limiter is designed with two varistors that are connected in parallel to the input terminals (ter-

minals L and N or L1, L2, L3 and N against PE). The required test 6kV / 3kA—1.2 / 50μs was performed

and the varistors are suitable for use in a 300V CAT IV environment. The supply voltage is protected by

an external fuse with the specified value and breaking capacity, type: aM 2A 500V / 120kA 10x38mm.

∅

When using two varistors in parallel, it is ensured that the limit value of the overvoltage category is ob -

served even if one varistor is defective (in case of one fault).

Operational risk with additional measures:

As a consequence of the protective measures taken, no operational risk arises.

4. Used symbols

Warning! Electric shock hazard!

Danger! Read the instructions!

The CE marking guarantees compliance with European directives and EMC regulations.

IP20

Anti-touch protection, anti-ingress of objects larger than 12.5mm,

∅

without water protection.

This product must not be disposed of in a household waste bin but must be disposed of in such a

way as to ensure its environmentally friendly recycling.

~

/

=

Alternating voltage, AC / direct voltage, DC.

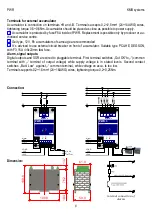

5. Installation

The person installing the system is responsible for safety of whole system containing the PWR.

Installation:

PWR is installed on DIN 35 rail in standard manner. Natural circulation of the air in the cubicle should be

ensured. Clarence of 50mm above and below PWR should be maintained.

No heat sources should be located bellow PWR.

Supply voltage:

Supply voltage have to be connected to L, N terminals resp. L1, L2, L3, N terminals through circuit

breaker. CB should be located in close distance to PWR on accessible place for operator. Circuit breaker

should be properly marked. Proper fuse and disconnecter housing should be used (i.e. OPVP10 and fuse

PVA10 2A aM, 500V/120kA,

∅

10x38mm, see accessories), Alternative fuses should be consulted with

producer.

Terminals accepts 0,2÷4mm

2

(24÷12AWG) wires, tightening torque 0,5÷0,6Nm.

Protection Earth, PE terminal,

have to be connected with 4mm

2

(12AWG) wire directly without

circuit breaker. Tightening torque 0,5÷0,6Nm.

Supply inputs are polarity free.

Output voltage:

Output voltage is on terminals + and -. Terminals are doubled for easier wiring. Terminals accepts

0,2÷2,5mm

2

(24÷14AWG) wires, tightening torque 0,5÷0,6Nm.

Conductors of proper cross-section have to be used depending on current and voltage loss.

3