14

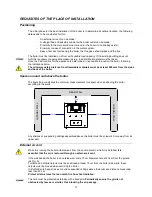

If it is not possible to realise the air vent in the wall behind the boiler, make the hole in a perimeter

wall where the boiler is installed.

If it not possible to realise the external air vent in the same room where the boiler is installed, this

hole can be made in an adjoining room as long as this room communicates permanently, by means

of a transit hole (15 cm minimum diameter).

The UNI 10683 Standard PROHIBITS the withdrawal of combustion air from garages,

combustible material warehouses, or from businesses where there is a fire hazard.

Do not connect the external air vent to the boiler

through piping. If there are other heating or

suction appliances in the room, air vents must guarantee an air volume required for the

proper operation of all devices.

Only sealed equipment (e.g. C type gas equipment, according to the UNI 7129 Standard) or

equipment that does not cause lower pressure compared with the external environment can

pre-exist or be installed in the place where the boiler

must be installed.

Extractor fans can cause functioning problems to the boiler when they are installed in the same room

or space where the appliance is found.

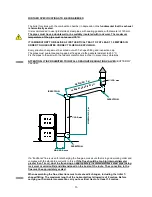

Fig. A

20 cm

Fig. A

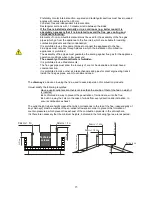

Flue and connection to the same flue - Chimney

The

flue

is a fundamental component for correct functioning of the boiler. The minimum section

of the flue must be that indicated in the boiler technical features (120 mm). Each boiler must be

equipped with its own flue, without other intakes (boilers, chimneys, stoves etc…). Flu e

dimensions are closely related to its height, which must be measured from the boiler flue gas

outlet to the chimney base. In order to guarantee draught, the chimney flue outlet surface must

be twice as big as the flue section.

The combustion product exhaust pipe, which is generated by the forced draught appliance, must

respond to the following requisites:

Combustion products sealed, waterproof and suitably isolated and insulated in the same

way as the conditions of use (see UNI 9615);

Made of suitable materials in order to resist to normal mechanical stress, heat, action of

the combustion products and condensation if any;

Upward alignment after the vertical tract throughout the remaining pathway with 5%

minimum gradient. The sub-horizontal alignment part must not have a length greater than

¼ of the effective height of the flue or chimney and it must not however be longer than

2,000 mm;

Summary of Contents for pellet boiler 24

Page 1: ...Pellet boiler PELLET BOILER 24 INSTALLATION USE AND MAINTENANCE USEFUL ADVICE User guide EN ...

Page 2: ......

Page 4: ...4 ...

Page 47: ...47 ...