1) Adjusting the pressure and gas flow rate to the main burner

This boiler operates on the flame modulation principle. It has two fixed pressure values which are minimum and

maximum and must be shown in the following table, whichever type of gas is used.

Note – Because correct minimum and maximum pressure are critical to the efficient operation of the boiler it is

essential that the following adjustments are carried out by qualified personnel only.

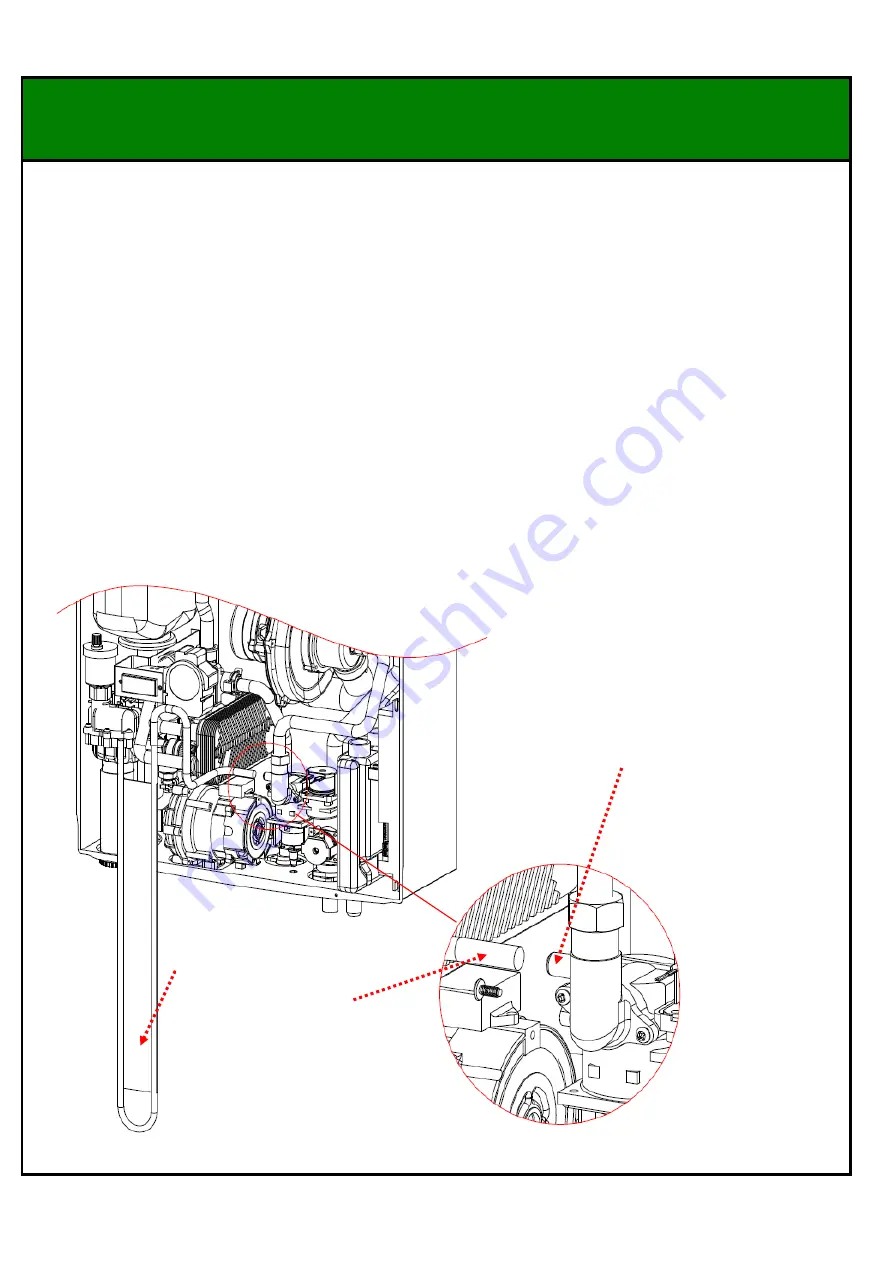

2) Adjusting minimum and maximum pressure gas valve (TIME, UP33-06)

①

Undo the screw “A”.

②

Connect suitable pressure gauge (Analogue – Water columns, Digital – Digital manometer) to burner test point

with silicone tube “B” downstream of the gas valve.

③

Operate boiler for central heating

④

After setting DIP S/W Nr 8 to the “ON” position, adjust potentiometer “C” on the main board at the minimum.

⑤

Adjust minimum pressure by rotating screw “D” clockwise to reduce pressure and anticlockwise to increase pressure.

⑥

After adjusting the minimum pressure, turn OFF position the DIP S/W Nr 8.

⑦

And then, After setting DIP S/W Nr 9 to the “ON” position, adjust potentiometer “D” on the main board at the maximum.

⑧

Adjust maximum pressure by rotating screw “E” clockwise to reduce pressure and anticlockwise to increase pressure.

3-5 Adjustment and gas Conversion

Water column

silicone tube

Screw for soundness

Burner 2

nd

pressure test point

Water column

25페이지