-16-

-17-

to the «+» welding cable socket, and the

cable with the “Mass” clamp to the «-»

welding cable socket

6.

Turn the machine mode switch

(see Fig. p.11, item 6) to MMA welding

position.

7.

Connect the “Mass” terminal to the

workpiece or welding table.

8.

Insert the electrode into the elec-

trode holder.

9.

After you make sure that the elec-

trode holder and the electrode do not

touch the parts connected to the neg-

ative terminal, connect the machine to

the mains power supply and turn it on.

10.

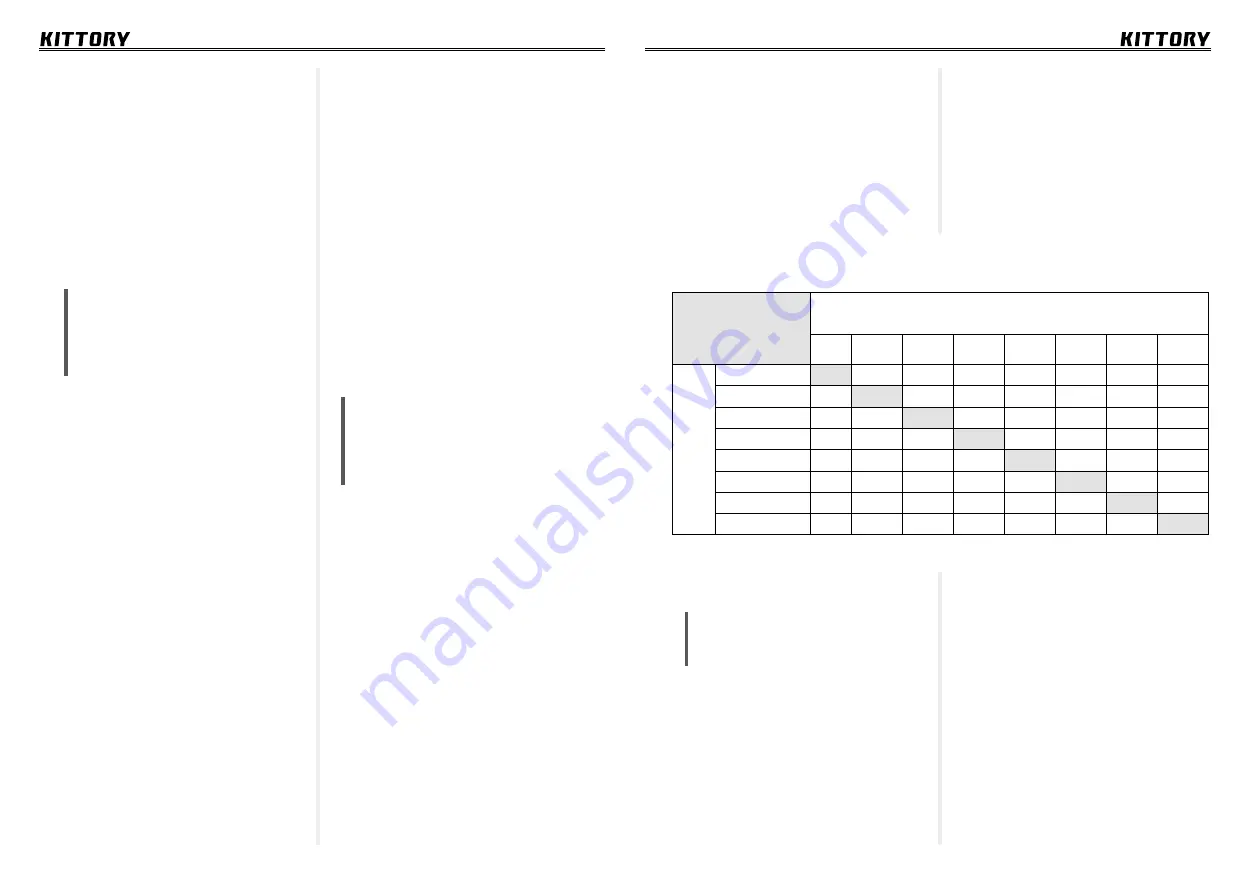

Set the required welding current

Electrode diameter, mm

Metal thickness, mm

0,5

1-2

3

4-5

6-8

9-12

13-15

16

W

elding current, A

10-20

1

30-45

1,5-2

65-100

2-3

100-160

3-4

120-200

4-5

150-200

4-5

160-250

5

200-350

6-8

Table of selecting electrode

diameter depending on the metal

thickness and welding current

Maintanence

ATTENTION!

Disconnect power

source before performing any

maintanence work.

Long service life and efficient oper-

ation of the welding machine directly

depend on its technical condition.

Regularly monitor the machine con-

dition. If damage occurs, repair the

machine immediately. Do not oper-

ate the machine in overload condi-

tion. Strictly observe the switching

frequency. Avoid impacts or other

mechanical damage of the case and the

machine operational panel. Do not keep

the machine in moist or damp areas.

Inverter welding machine is a reli-

able equipment. Observance of simple

safety rules and timely maintenance can

significantly increase the operational

lifespan.

Keep the welding machine in good

condition.

Carry out preventative maintanance

and timely repairs of the machine.

(see Fig. p.11, item 1) and start work.

Maintanence

arc damage and the welding process

shutdown.

6.

Setting the wire feed speed: The

wire feed speed control (see Fig. 11,

item 4) controls the speed of the wire

that is being fed through the MIG torch.

The wire feed speed must be precisely

set at the level when the wire fully

melts. When setting the wire feed speed,

check the wire type, diameter, volt-

age and positioning of the seam. The

welding current changes if the wire feed

speed adjusted.

NOTE:

The wire will move faster

if you do not strike the welding

arc. On the contrary the wire feed

speed will be lower if you strike

the welding arc.

7.

Connect the earth terminal to the

metal part identical to the one you will

be welding on. The metal part should be

the same thickness or slightly thicker

than the workpiece. Clean the workpiece

before you start welding.

8.

Adjust the required welding

voltage.

9.

Bring the torch close to the work-

piece, make sure to position the torch

following the recommendations of this

manual.

10.

With your free hand, turn the wire

speed control knob to the maximum and

keep holding the knob.

11.

Draw the protective mask and

press the MIG torch trigger to strike the

arc, start moving the torch forehand

or backhand, simultaniously turn-

ing the wire feed speed control knob

counterclockwise.

12.

While adjusting the wire feed

speed, the sound produced by the

welding arc will change from the sharp

buzzing sound to a slight sizzling bacon

sound. If you reduce wire feed speed

too much, you will hear a sharp sound

and bangs. The wire feed speed is

correct when you hear a steady sizzling

sound. By slightly changing the wire

feed speed, you can control the tem-

perature and fill rate of the weld when

the arc voltage settings are set and not

changed. Repeat the above procedure if

you have adjusted the voltage, diameter

or type of the welding wire.

13.

After welding operations are

completed, set all the controls to the

minimum position, close the valve on

the cylinder and unplug the machine.

MMA operation

ATTENTION!

Follow the safety

rules! Start work only in appro-

priate tightly woven clothes and

closed boots. Welding gloves and

a mask must be worn at any time!

If the welding machine was used

for welding in the MIG mode, take the

following steps to prepare it for opera-

tion in the MMA welding mode (covered

electrode welding):

1.

Unplug the welding machine.

2.

Turn the gas cylinder valve off and

disconnect the hose from the socket on

the back of the welding machine.

3.

Disconnect the MIG torch. Loose

the feeder deflector roll and coil the wire

onto the spool.

4.

If the polarity of the negative termi-

nal has been changed to «+», restore it.

(See step 4 on page 13 of this manual).

5.

Connect the welding cables to the

machine: connect the electrode holder

MMA operation