-14-

-15-

MIG operation

6.4. Adjust the pressure roll force

(see Fig. 13, tem 3) so that it is not

clamped too tightly, and the wire does

not slip. Excessive clamping will lead to

premature wear of the pressure roll, while

slippage will complicate the welding

process.

6.5. Remove the MIG nozzle and a

conductive head from the torch, press

the torch trigger, pull the wire until it

emerges from the torch port.

6.6. Connect the conductive head

that exactly matches the wire diameter

to the torch and place the nozzle back

to its place.

6.7. Adjust the length by clipping off

the end of the wire with insulated cutters.

Repeat each time before starting work.

MIG operation

WARNING!

Never operate the

maching in wet weather or in a

humid room.

Never use cutting tools (drills,

grinders, electric saws, etc.) next

to the machine. Metal dust may

enter the machine and it will lead

to its damage.

Never carry out welding work if wire

or main supply cables are damaged.

Before switching on, keep the

machine for at least two hours at

a positive ambient temperature to

prevent condensation.

1.

Turn on the power switch (see Fig.

p. 11, item 12), the power indicator light

will turn on (see Fig. p.11, item 2).

2.

Select the MIG mode with the machine

mode switch (see Fig. p.11, item.6).

3.

Set the desired value with the weld-

ing current selector (see Fig. p.11, item 5).

The welding current selector controls

the temperature of the welding arc.

4.

Positioning of the MIG welding

torch: The best position of the welding

torch is the position convenient to com-

fortably hold it. In the process of using

your welding machine, try to keep the

torch in various positions until you find

the most convenient for you.

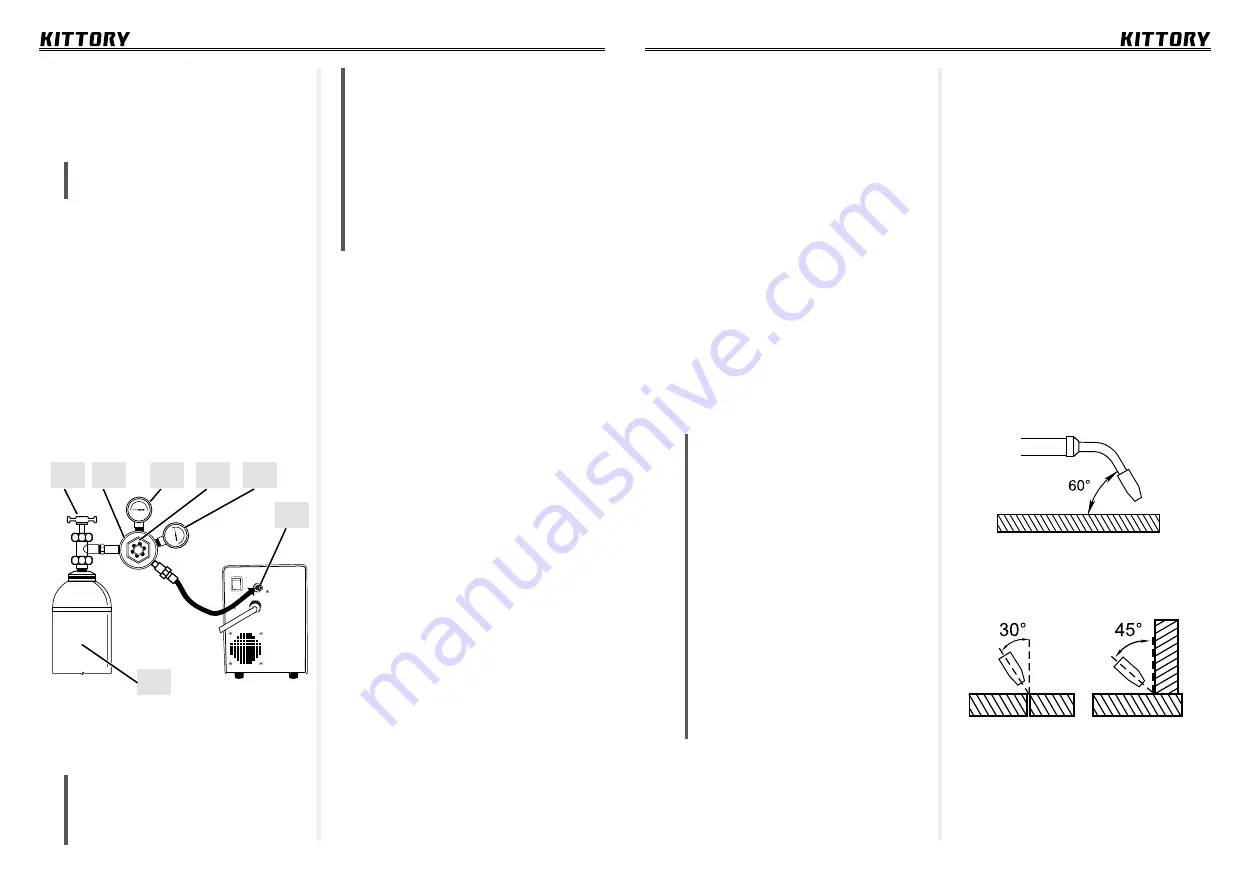

There are two major torch angles

which must be taken into account when

carring out welding works.

Angle A

may vary, but in most cases it

should be 60°. This is the angle at which

the torch handle is parallel to the weld-

ing seam. When the angle is greater,

the fill rate is higher. When the angle is

smaller, the fill rate is lower.

Angle B

can be applied in two cases:

to better see the arc for greater control

of the pool fill rate and for arc force

control.

5.

The distance between the con-

tact head of the welding torch and the

surface to be welded must not change

and should not exceed 6mm. A greater

distance will result in the welding

MIG installation

5.1. Connecting gas cylinder: Install

the gas cylinder on the prepared sur-

face. If necessary, fix it to avoid tipping

over.

ATTENTION!

Observe safety rules

when working with a gas cylinder!

5.2. Attach the gas regulator to the

cylinder valve.

5.3. Attach the gas hose of the gas

cylinder regulator outlet to the gas cylin-

der connector (see Fig. p. 11, item 11).

Gas cylinder connection diagram:

1 –Cylinder valve;

2 – Regulator;

3 – Cylinder pressure gauge;

4 –Pressure control valve;

5 – Gas flow meter gauge;

6 –Gas cylinder connector;

7 –Gas cylinder.

5.4. Set the required gas flow by turn-

ing the regulator knob.

Note:

The wire diameter, welding

current and welding speed affect gas

consumption. The average gas

consumption for welding construc-

tional steels with a welding wire diam-

eter of 0.8 and 1.0mm with welding

current of 60-160 is 8-9 l/min.

Gas consumption for non-ferrous

metals is usually 1.5-2 times higher.

When working in windy conditions

outside or inside in a draught,

protect the welding area from

blowing-out of the shielding gas.

5.5. Connect the device to the power

supply and switch on the automatic

switch on the back panel (see Fig. p. 11,

item 12).

5.6. Press the torch trigger and make

sure that the gas flows through the

gas valve into the torch. The gas valve

is located on the back of the welding

machine panel and is activated by press-

ing the trigger on the MIG torch. When

gas flows, listen for a hissing sound.

6.

Electrode wire. The type and thick-

ness of the wire is selected depending on

the chemical composition of the material

to be welded and its thickness. Welding

wire diameter is selected in accordance

with the required welding current level.

Most often, a wire with a diameter of

0.8 mm is sufficient for welding metal

with a thickness of 1 to 4 mm. The most

common wire brand for welding car-

bon-constructional steels is ER70S-6.

6.1. Install the wire weld coil in the

feeder (see Fig. p. 13, item 1).

6.2. Make sure that the deflector roll

is installed in a way that the groove

matches the wire diameter. If needed,

turn the roll over by untwisting the lock-

ing screw (see Fig. p. 13, item 5).

6.3. Insert the wire into the feeder

and press it with the pressure roll (see

Fig. p. 13, item 3).

7

6

1

2

3

4

5