-10-

-11-

General welding information

2

1

4

3

5

6

7

8

9

10

11

12

13

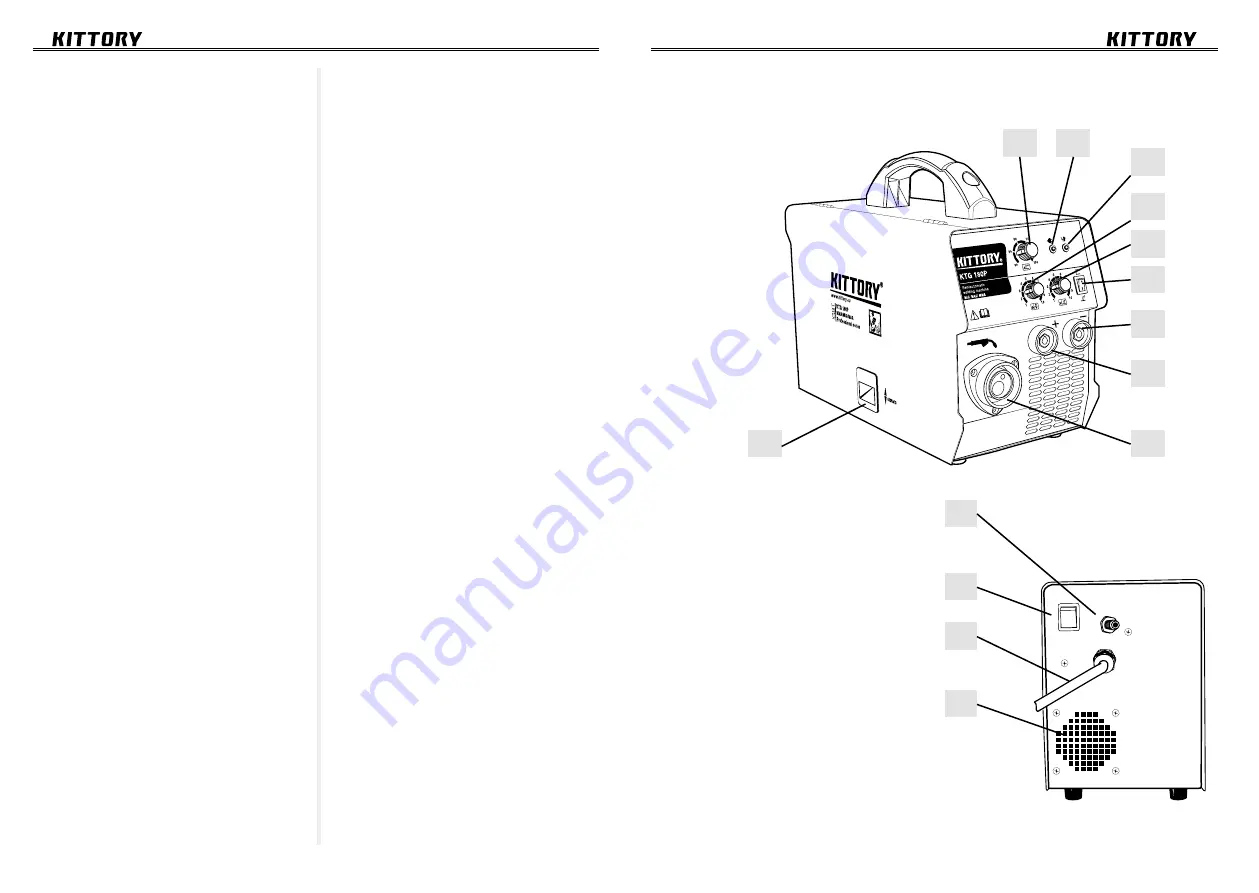

14

Physical configuration and controls of KTG 160P, KTG 180P, KTG 200P

11.

Gas cylinder connector.

12.

Power switch button.

13.

Power supply cord.

The power-supply cord is designed

for power connection of the welding

machine to an electric power network

rated at 150-230Volts, 50Hertz. For

reliable power supply of the welding

machine, an outlet with a grounding

contact and a circuit breaker with a cur-

rent rating of at least 50A are required.

14.

Cooling fan grid

General welding information

General welding

information

Semiautomatic welding machine is

designed for manual inert-gas arc weld-

ing. The shielding gas or gas mixture

may consist of the following: carbon

dioxide, argon or their mixture.

The welding machine has a metal

case with an opening wall. On the

front panel there is the welding current

selector, the wire feed speed control,

the power indicator, alarm indicator. The

machine is equipped with a forced venti-

lation system, therefore, it is strictly for-

bidden to cover any ventilation openings

in the metal case.

The principle of semiautomatic

welding machine. The machine converts

an AC voltage of 50Hz into a 400V DC

voltage that is converted to a high-fre-

quency modulated voltage and rectified.

Welding is carried out by a melted elec-

trode in a shielding gas environment.

The electrode is a metal wire fed by feed

rolls into the weld pool.

The shielding gas is fed to the

welding pool from the attached cylinder

through the solenoid valve. The machine

has built-in protection against overheat-

ing and is equipped with current adjust-

ment conrol and wire feeder control,

depending on the material and the thick-

ness of the workpiece to be welded.

Component overview

1.

MMA welding current. Welding

current is selected depending on the

electrode diameter and thickness of the

workpiece.

2.

Power indicator. Indicates that the

welding machine is connected to the

electrical power supply.

3.

Alarm indicator. If the alarm indi-

cator light is on, the machine is over-

heated. When the breaker has tripped,

the power flowing to the electrical

circuit is interrupted, but the cooling

fan keeps working. After the operating

temperature has been restored, the cur-

rent supply to the output of the welding

machine is automatically switched on.

4.

MIG wire feed speed control

The welding current depends on the

feed rate of the electrode wire. The wire

feed speed prevents excessive weld

spatter, wire sticking to the workpiece or

arc breaking.

The wire feed speed is selected

experimentally and depends on the

wire diameter, the thickness of the

weld metal and the qualification of the

welder.

When welding current increases,

weld penetration increases too, it leads

to an increase in the proportion of the

base metal in the seam. The width of

the seam increases slightly at first, and

then decreases.

5.

Arc voltage regulator

When arc voltage increases, weld

penetration decreases and the width of

the seam increases. Excessive increase

in arc voltage leads to increased spat-

tering of melted metal, deterioration of

the gas shield and formation of pores in

the weld metal.

The arc voltage is set depending on

the selected welding current amperage.

6.

MIG/MMA switch.

7.

(–) “Mass” or negative welding

cable socket 10-25 mm

2

.

8.

(+) Positive welding cable socket

10-25 mm

2

.

9.

MIG torch line cable inlet.

10.

Wire feeder door lock.