KisanKraft

®

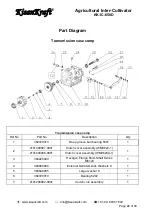

Agricultural Inter-Cultivator

KK-IC-650D

: +91.80. 6835 7800

Page 17 of 49

5.3 Pay attention to the oil level of Diesel engine, walking case and gear box. When they are

insufficient, please refuel them.

5.4 Never cool the Diesel engine in the way of water-pouring.

5.5 Prevent Intercultivator from falling down when Intercultural/weeding operations.

5.6 Never install Intercultivator with rotary blades when walking on sand or stone to avoid

damaging blades.

5.7 After Intercultural/weeding operations, please clear away dirtiness on the Intercultivator, such

as mud, grass and

Maintenance

Due to rotary situation, abrasion and load change of mini weeder, bolts will become loose, and parts will be

worn during the work. These changes will destroy the proper working state of mini weeder, create abnormal

fitting clearance, degrade output of Diesel engine, increase oil consumption, lead to the maladjustment of

spare parts, increase malfunction of mini weeder. All these will seriously affect the working efficiency of mini

weeder. To decrease the frequency of the above-mentioned accidents, prevention of maintenance work

must be done strictly and regularly to keep the mini weeder in a good technical state and prolong its life.

◆

1. Running-in of mini weeder

◇

1.1 As for running-in of Diesel engine, please refer to its instruction.

◇

1.2 If mini weeder is new or is just heavily repaired, it should work without load for one hour.

After the mini weeder works with light load for five hours, all oil in gear box and crankcase of Diesel

engine should be drained immediately. Afterwards, you should refuel adequate clean Diesel oil, pull

the starting grip 5~10 times, then drain it. Refuel the lube oil for 4 hours running-in, then can use

the weeder normally.

◆

2. Technical maintenance table of mini weeder

◇

2.1 Every-time maintenance (before and after work)

•

Listen and check if there is malfunction of every part (such as abnormal noise, overheat,

loose screw and so on).

•

Check if there is oil leakage from Diesel engine, gear box and running gear.

•

Check if the oil level of Diesel engine and gear box is between the upper and lower limit

of dipstick.

•

Clean the whole machine and spare parts which are with mud, grass, and oil stain

regularly.

•

Do daily record.

◇

2.2 Primary maintenance (per 150 hours)

•

Carry out maintenance work based on all contents of every-time maintenance.

•

Wash gear box, running gearbox and change lube oil.

•

Check and adjust clutch, shift system and reverse gear system.

◇

2.3 Secondary maintenance (per 800 hours)

•

Carry out maintenance work based on all contents of primary maintenance.

•

Check all gears and bearings. If they are fretted severely, please replace them.

•

Check other parts of mini weeder, such as: rotary blades or bolts and so on. If there is

damage, please replace them.

◇

2.4 Technical inspection (per 1500-2000 hours)

•

Take the whole machine to the specific maintenance station and have a check. If the

spare parts are severely fretted, they must be changed or repaired according to the

situation.