D

OCUMENT

301900,

R

EVISION

D

46

E

PI

S

ENSOR

U

SER

G

UIDE

User-Supplied Cable

If you are using your own cable, be sure that is has sufficient conductors of

the required wire gauge for your installation and that it provides adequate

shielding to maintain the noise performance of the EpiSensor. The

conductors used for the signals and the control signals (Cal and CCE) carry

little current. The table in the section above shows the resistance and

calculated voltage drop for different lengths of cables when using an Altus

recorder. You can substitute your own values to calculate the allowed cable

length.

In order to exceed these lengths, use a regulated power supply that supplies

12-15 V. Calculate the voltage drop in the cable at the maximum supply

current and make sure that it meets the minimum operating voltage for the

chosen configuration.

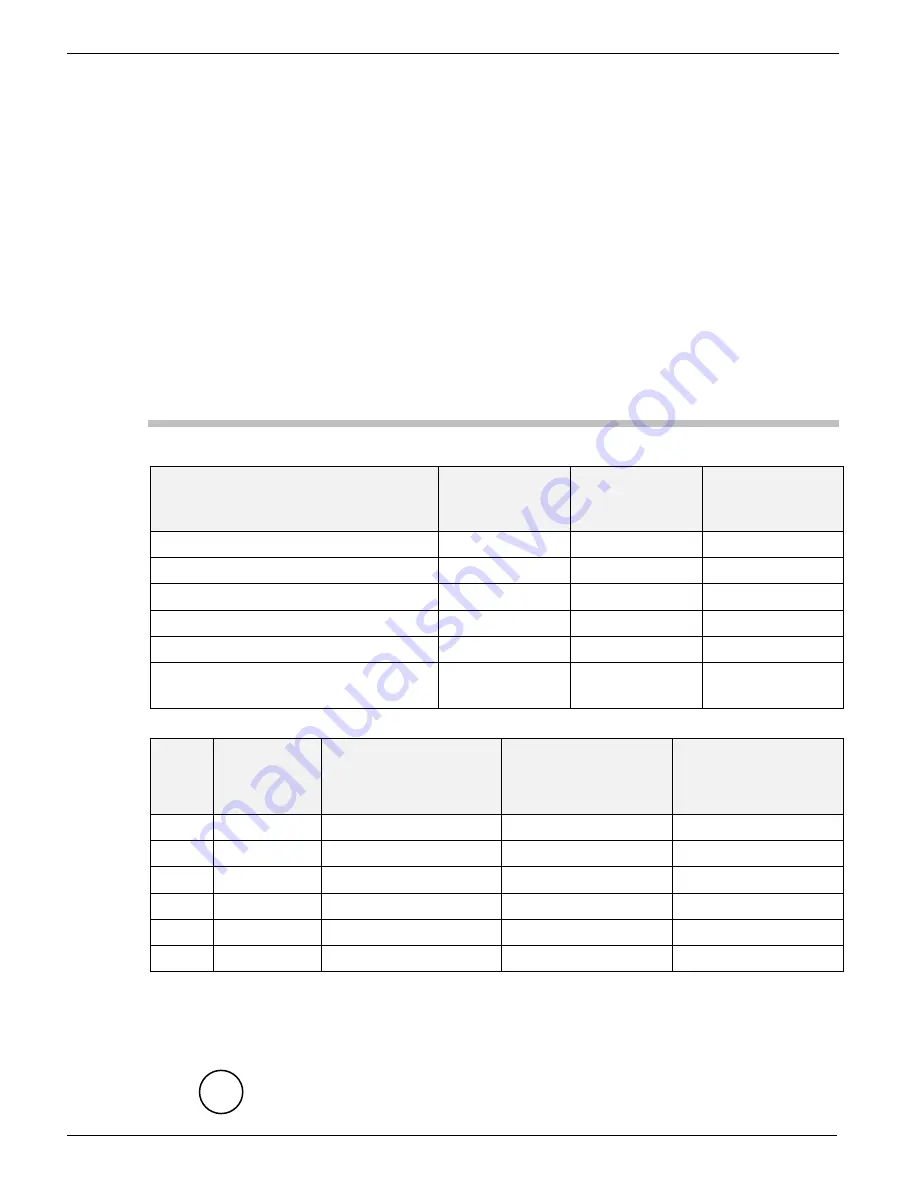

Table 9: EpiSensor cabling requirements (1 foot = 0.3048 meters)

Sensor Type

EpiSensor low-

power, 2g,

2.5V S/E

EpiSensor low-

noise, 2g, 5V

differential

EpiSensor low-

noise, 2g, 20V

differential

Sensor minimum operating voltage

10.0

10

11.5V

Maximum supply current

30.0

52

70mA

Minimum supply voltage

11.6

11.6

11.6V

Allowed cable voltage drop

1.6

1.6

0.1V

One-way allowed cable drop

0.8

0.8

0.05V

One-way allowed resistance

at full-scale output

26.7

15.4

0.7 Ohms

Cable

AWG

Cable

Resistance

per 1000 Feet

Low-power 2g, 2.5V

Single-ended Maximum

Cable Run in Feet

Low-noise 2g,5V

Differential Maximum

Cable Run in Feet

Low-noise 2g, 20V

Differential Maximum

Cable Run in Feet

24

27.70

950

550

20

22

17.50

1500

880

40

20

10.90

2400

1400

60

18

6.92

3850

2200

100

16

4.35

6100

3500

160

14

2.73

9700

5500

260

Grounding

The cable assembly technique used for connecting the EpiSensor to an

Altus instrument is designed to allow future compliance with the

requirements of the emissions and immunity standards (EN 55022

CE