012420 / FLT-M02-0004

37

Kice Industries, Inc.

13. Appendix C

ASCO Valves

®

E255075 - 09/2015 All Rights Reserved.

I&M V_6583_R12

©

ASCO Valve, Inc.

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Page 1 of 4

I&M V_6583_R12

Installation&Maintenance Instructions

OPEN-FRAME, GENERAL PURPOSE, WATERTIGHT/EXPLOSIONPROOF SOLENOIDS

OPTIONAL FEATURE FOR OPEN FRAME (GENERAL PURPOSE) CONSTRUCTION ONLY

SERIES

8016G/H

— SERVICE NOTICE —

ASCO

™

solenoid valves with design change letter “G” or “H” in the

catalog number (ex. 8210G1) have an epoxy encapsulated ASCO Red

Hat II

®

solenoid. This solenoid replaces some of the solenoids with

metal enclosures and open

-

frame constructions. Follow these installation

and maintenance instructions if your valve or operator uses this solenoid.

DESCRIPTION

Catalog numbers 8016G/H1 and 8016G/H2 are epoxy encapsulated

pull-type solenoids. The green solenoid with lead wires and 1/2 conduit

connection is designed to meet Enclosure Type 1-General Purpose, Type

2-Dripproof, Types 3 and 3S-Raintight, and Types 4 and 4X-Watertight.

The black solenoid on catalog numbers pre

xed “EF” is designed to meet

Enclosure Types 3 and 3S-Raintight, Types 4 and 4X-Watertight, Types 6

and 6P-Submersible, Type 7, Explosionproof Class I, Division1 Groups

A, B, C, & D and Type 9, -Dust-Ignitionproof Class II, Division1 Groups

E, F & G. The Class II, Groups F & G Dust Locations designation is

not applicable for solenoids or solenoid valves used for steam service or

when a class “H” solenoid is used. See

Temperature Limitations

section

for solenoid identi

cation and nameplate/retainer for service. When

installed just as a solenoid and not attached to an ASCO valve, the core

has a 0.250-28 UNF-2B tapped hole, 0.38 minimum full thread.

Series 8016G/H are also available in:

•

Open-Frame Construction:

The green solenoid may be supplied

with 1/4

spade, screw or DIN terminals. (Refer to Figure 4)

□

DIN Plug Connector Kit No. K236034:

Use this kit only

for solenoids with DIN terminals. The DIN plug connector kit

provides a two pole with grounding contact DIN Type 43650

construction (See Figure 6).

•

Panel Mounted Construction:

These solenoids are speci

cally

designed to be panel mounted by the customer through a panel

having a .062 to .093 maximum wall thickness. (Refer to Figure 3

and section on

Installation of Panel Mounted Solenoid

).

•

Junction Box:

This junction box construction meets Enclosure

Types 2, 3, 3S, 4, and 4X. Only solenoids with 1/4

spade or screw

terminals may have a junction box. The junction box provides a

1/2

conduit connection, grounding and spade or screw terminal

connections within the junction box (See Figure 5).

OPERATION

When the solenoid is energized, the core is drawn into the solenoid base

sub-assembly.

IMPORTANT: When the solenoid is de-energized, the initial return

force for the core, whether developed by spring, pressure, or weight,

must exert a minimum force to overcome residual magnetism created

by the solenoid. Minimum return force for AC construction is 0.69lbs

(3.1N) and 0.31 lbs (1.38N) for DC.

INSTALLATION

Check nameplate for correct catalog number, service, and wattage. Check

front of solenoid for voltage and frequency.

WARNING:

Electrical hazard from the

accessibility of live parts. To prevent the possibility

of death, serious injury or property damage, install

the open - frame solenoid in an enclosure.

FOR BLACK ENCLOSURE TYPES 7 AND 9 ONLY

CAUTION: To prevent

fi

re or explosion, do not install

solenoid and/or valve where ignition temperature of

hazardous atmosphere is less than 165°C. On valves used for

steam service or when a class “H” solenoid is used, do not

install in hazardous atmosphere where ignition temperature

is less than 180°C. See nameplate/retainer for service.

NOTE:

These solenoids have an internal non-resetable thermal fuse to

limit solenoid temperature in the event that extraordinary conditions occur

which could cause excessive temperatures. These conditions include high

input voltage, a jammed core, excessive ambient temperature or a shorted

solenoid, etc. This unique feature is a standard feature only in solenoids

with black explosionproof/dust-ignitionproof enclosures (Types 7 & 9).

CAUTION: To protect the solenoid valve or operator, install

a strainer or

fi

lter, suitable for the service involved in the inlet

side as close to the valve or operator as possible. Clean

periodically depending on service conditions. See ASCO

Series 8600 and 8601 for strainers.

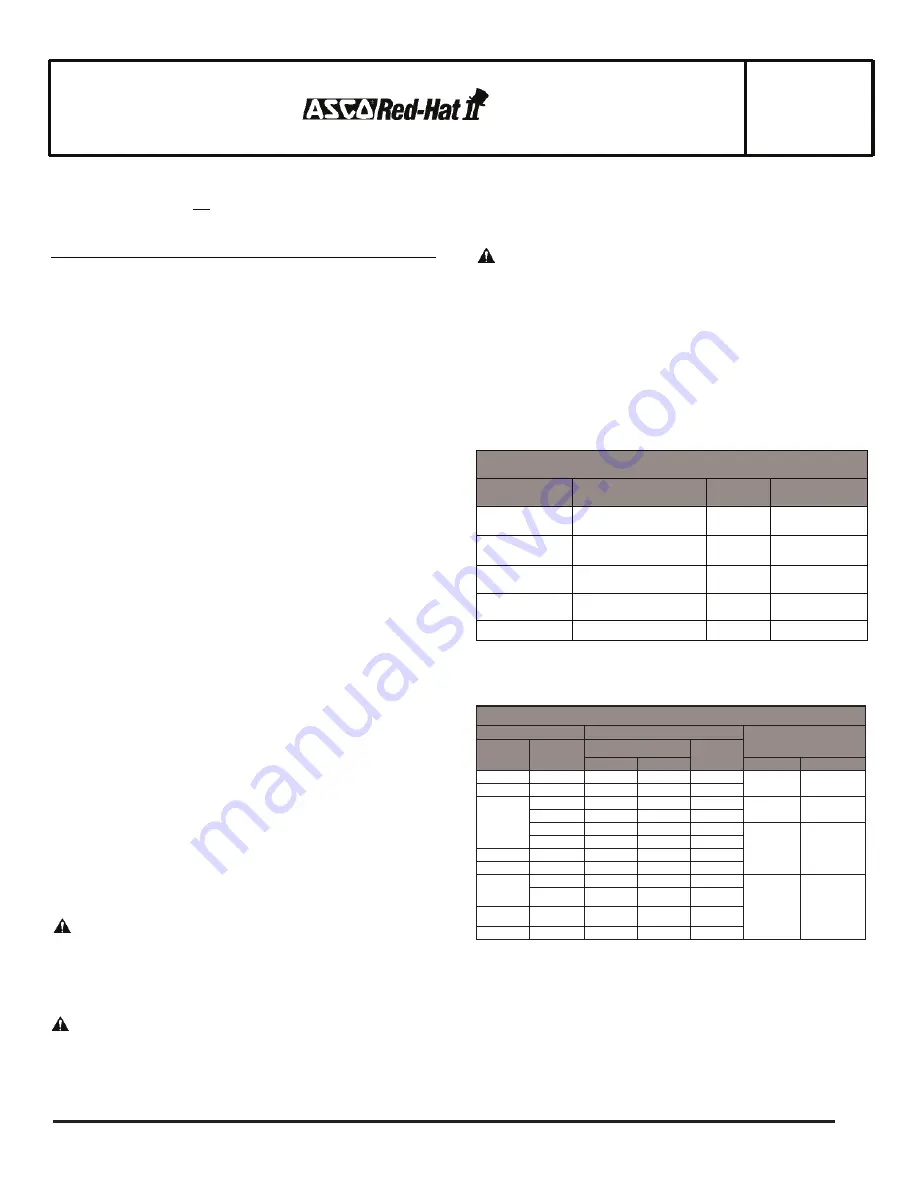

Temperature Limitations

For maximum valve ambient temperatures, refer to chart. The temperature

limitations listed, only indicate maximum application temperatures for

eld wiring rated at 90

°

C. Check catalog number pre

x and watt rating

on nameplate to determine maximum ambient temperature. See valve

installation and maintenance instructions for maximum

uid temperature.

NOTE:

For steam service, refer to

Wiring

section,

Junction Box

for

temperature rating of supply wires.

™

§ Minimum ambient temperature -40°F (-40°C).

* When used with watertight aluminum junction boxers (screw or spade) max.

ambient and

uid temperature will be reduced to 157°F (69.4°C)

** 10.6 Watt solenoids rated for 104°F are 8030, 8260, 8316, 8321, 8320, 8360

& 8344 valves while those rated for 140°F are 8040 valves

Temperature Limitations for Series 8003H, 8007H and 8202H solenoids

Watt Ratings

Maximum Ambient

Temperature

Pre

x

Coil

Class

AC

DC

60 Hz

50 Hz

°C

°F

EF

FT

6.1

8.1

-

52

125

EF

FB

9.1

11.1

-

FT

6.1

8.1

-

55

131

FB

9.1

11.1

-

HT

-

-

10.6

40

104

HB

-

-

18.6

EF

HT

-

-

10.6

EF

HB

-

-

18.6

HT

6.1

8.1

-

60

140

HB

9.1

11.1

-

EF

HT

6.1

8.1

-

EF

HB

9.1

11.1

-

= EF data applies to Explosionproof coils only.

= Some DC solenoid valves can be operated at maximum ambient

temperature of 55°C / 131°F with reduced pressure ratings. See valve

I&M for maximum operating pressure differential ratings.

= Steam Service Valves have a maximum ambient temperature of 55° C/

131°F.

Positioning

This solenoid is designed to perform properly when mounted in any

position. However, for optimum life and performance, the solenoid

should be mounted vertically and upright to reduce the possibility of

foreign matter accumulating in the solenoid base sub

-

assembly area.

Temperature Limitations For Series 8016G Solenoids for use on Valves

Rated at 6.1, 8.1, 9.1, 10.6 or 11.1 Watts

Watt

Rating

Catalog

Number Coil Pre

x

Class of

Insulation

Maximum §

Ambient Temp.

6.1, 8.1, 9.1 &

11.1

None, FB, KF, KP,

SC, SD, SF & SP

F

125°F (52°C)

6.1, 8.1, 9.1 &

11.1

HB, HT, KB, KH, SS, ST

& SU

H

140°F (60°C)

10.6**

None, KF, SF, SC, HT,

KH, ST & SU

F & H

104°F (40°C)

7.1 @ 60Hz

(8.1 @ 50Hz)

F & H

175°F (79°C)*

10.6**

F & H

140°F (60°C)