13

OPERATION

WARNING:

THE CHEESE MELTER AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING, CLEANING OR SERVICING

THE CHEESE MELTER.

CONTROLS

Angled Handle

—Elevates or lowers the broiling drawer and grate to different positions. Grasp the handle and pull

towards Cheese melter cavity. This releases the mechanism and allows the lifting handle to move into the desired position.

Burner Valve

— Regulate the flow of gas to the burners. Gas flow is increased by turning the valve counterclockwise.

Drip Tray

—Collects grease and waste which is diverted by the drip shield.

DO NOT allow the drip tray to overflow. Empty the drip tray when three-quarters full to reduce the possibility of spillage.

Drawer Handle

—Pull the drawer out for loading and unloading. To operate, pull straight out.

LIGHTING, RELIGHTING, AND SHUTDOWN INSTRUCTIONS

1. Turn burner valve to the OFF position and wait 5 minutes.

2. Light the pilot adjacent to the main burner. Adjust the pilot valve screw until the pilot flame has a slight yellow tip.

3. After the pilot has been established, turn the burner valve to the ON position.

4. If the burners fail to light, turn off all valves, wait 5 minutes and repeat steps 1 -3.

5. To shut down, turn the burner valve to the OFF position.

RACK POSTION AND GAS SETTING

Each operator will find the optimum rack position and gas setting for various products; however, it is recommended that

gas input be reduced first when lower rack temperatures are desired. Further reduction in rack temperatures, if

necessary, can then be obtained by lowering rack position. Infrared burner must use the full on gas setting.

CLEANING

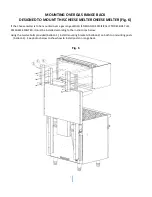

1. Allow Cheese melter to cool.

2. To remove Cheese melter rack for cleaning, adjust Cheese melter rack to center position.

3. Position left and right hands simultaneously on edges of Cheese melter rack and raise both rack stops.

4. Slide Cheese melter rack and drip tray forward past rack stops, (which must be pivoted out of the way)

holding tray up against racks.

5. Remove Cheese melter rack and drip tray from Cheese melter.

6. Let back of tray drop down to vertical to allow front hooks to disengage.

7. Remove drip pan from Cheese melter rack and clean as you would any normal utensil, using care not to

damage the front hooks

8. To replace, hook the drip tray to the Cheese melter rack while tray is in a vertical position.

9. Replace Cheese melter rack and drip tray in side channels while holding tray up close to rack.

10. Clean bottom pan. Slide pan out and wash with soap and water. Rinse thoroughly and wipe dry with a soft

clean cloth.

11. Clean stainless steel surfaces with a mild detergent and water, using a damp cloth, or with a commercial

stainless steel cleaner. Rinse thoroughly and wipe dry with a soft clean cloth.

12. Burner ports and throats should be thoroughly cleaned. Venturi must be free from grease and lint.

DO NOT

insert tooth pick or any sharp object in burner port holes.

MAINTENANCE

WARNING:

THE CHEESE MELTER AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING, CLEANING, OR

SERVICING THE CHEESE MELTER.

LUBRICATION:

Burner valve stems must be lubricated. Upon sticking, a burner valve stem should receive

maintenance from your local authorized servicer.

PILOT LIGHTS:

Pilot lights are to be kept clean and adjusted at the proper flame height.

VENT:

Annually, when the Cheese melter is cool, check the flue and clear any obstructions.

SERVICE AND PARTS IN FORMATION:

Contact your local Service Agency to obtain service and parts information.