K4C COMPACT-MULTI – INSTALLATION/OPERATION MANUAL

K4C Compact-multi

Feb

-06

11

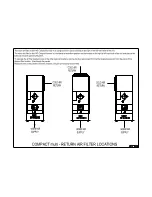

6.0 OIL TANKS & PIPING

Tank installation must conform to local requirements.

Install according to the applicable code. Minimize number of connections in suction line

and make all connections as tight as possible. Use a pipe joint compound suitable for

oil on all pipe threads. To reduce possibility of air leaks, tighten stem packing gland nut

on any valves installed in the suction line. Also, be sure the oil filter is tight, as filter

gaskets often shrink. Check for kinks in the oil lines as well as for possible air pockets

and for loose connections. Two filters as shown below are recommended. Further

information is available at

www.kerrheating.com

.

ONE PIPE SYSTEM

Where the tank is above the burner and when the oil flows

by gravity to the oil pump, a single-stage fuel unit with a

single oil line to the pump may be used.

TWO PIPE SYSTEM

When single line is unsuitable, use double line or see your

KERR dealer for special oil line fittings.

7.0 BLOWER REMOVAL

Use a reversing drill with 1/4” hex drive for the sheet metal screws.

The KERR K4C Compact-multi has a quick release blower suspension system that is

designed to be tight and rattle free.

a.

Remove front panel to blower compartment.

b.

Remove the screw (s) from the blower key. (Figure -2A)

c.

Remove the blower key and slide the blower towards the burner. (Figure -2B).

Replace the blower assembly using the reverse procedure. See diagram.

DO NOT

start the oil burner until installation is complete and all cleanout covers are secured in

place.