Anti-Cycling

Electric motors are often limited in the number of times they can be safely started

in an hour. This is particularly important in the operation of submersible bore

pumps. When a motor starts there is an initial inrush of current that produces

heat in the coils and iron rotor of the motor. If the frequency of starts is excessive

the accumulation of heat within the motor can cause severe damage and even-

tual failure of the motor. Submersible bore pump motors are particularly prone to

damage from excessive cycling (starting and stopping).

The anti-cycling option built into the T20 allows the user to set the maximum

number of times the pump can be safely started in any one hour period. If you

select yes to this option the screen that follows will ask you to enter the maximum

number of times the pump can be started in any one hour. The number of starts

can be set from 1 start per hour to 1800 starts per hour. Please contact your

pump supplier to obtain the correct figure for your specific pump. In operation the

anti-cycling system monitors both time and the number of starts and compares

the two. If the starts per hour rate is exceeded 10 consecutive times in any one

hour period the pump will be automatically shut down and the T20 will display a

message indicating the starts per hour rate was exceeded.

As a simple example of the way the anti-cycling system works, if the starts per

hour rate is set to 360 (one start every 10 seconds maximum) and the pump

started 9 times in a row at less than 10 seconds between each start and then

did not start again for 12 seconds the anti-cycling shutdown will not be invoked.

If however, the pump were to start 10 times in a row with less than 10 seconds

between the starts the anti-cycling system would be invoked and the pump would

be shut down.

In a conventional pressure system the anti-cycling function can be used to protect

the pump from damage in the event of the system’s air cell losing its air charge.

If air is lost from a system’s air cell due to a ruptured diaphragm or leaking air

valve, the pump will hunt on and off rapidly. Such rapid cycling will cause the

pump to overheat very quickly. The T20’s anti-cycling feature can be used to shut

down the pump and prevent damage in such a situation. To use the anti-cycling

function for this type of pump protection simply set the starts per hour to some

value that is marginally higher than the system’s normal start rate. This will avoid

nuisance tripping but will shut the pump down if excessive sequential cycling is

encountered.

28

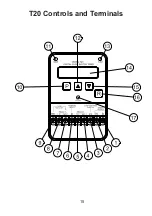

Summary of Contents for T20

Page 17: ...T20 Controls and Terminals 15...

Page 34: ......