19

6.11 Tach-Generator Feedback, J1

–

The KBRG-212D is

factory set for armature feedback which provides good

load regulation for most applications. For superior

load regulation analog tach-generator feedback can

be used.

Connect the tach-generator to J1, so that the polarity

of the tach-generator is the same with respect to the

input signal polarity.

Note:

If tach-generator is wired for reverse polarity,

the motor will run at full speed. See Figure 9.

7

SETTING SELECTABLE JUMPERS

The KBRG-212D has customer selectable jumpers which must be set before the control

can be used. See Figure 1, on page 10 for jumper locations.

7.1 J2 – Armature Current

– Select the J2 position (1.7, 2.5, 3.3, 5, 7.5) closest to the

rated motor current. See Figure 10 and Table 9.

Note:

The maximum output current is set to 150% of the J2 position, which may be reset

using the FCL and RCL Trimpots. See Section 10.3, on page 26.

FIGURE 9 –

J1 -TACH-GENERATOR

FEEDBACK

+ -

G

J1

+ -

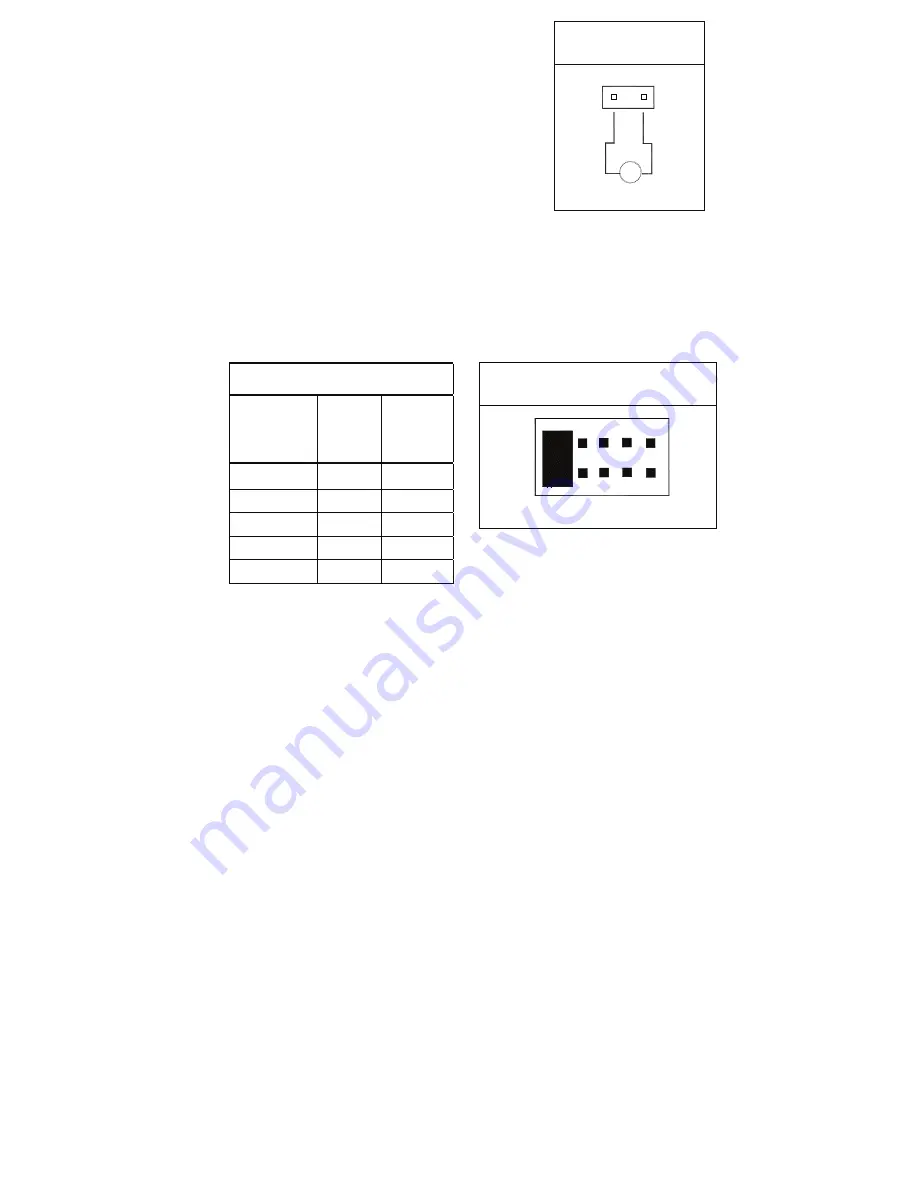

FIGURE 10 - J2 – ARMATURE

CURRENT JUMPER

(SHOWN IN FACTORY SETTING)

2.5A

7.5A

1.7A

3.3A

5.0A

J2

TABLE 9 –

MOTOR HORSEPOWER

J2 Position

Motor

Current

(DC Amps)

90 VDC

180 VDC

7.5A 3/4 1

½

5.0A 1/2 1

3.3A 1/3 3/4

2.5A 1/4 1/2

1.7A 1/6 1/3