30

2. Reasons why refrigerant piping shall be insulated

(1) The gas pipes and liquid pipes can become extremely hot or cool while in operation. Therefore, they should be

insulated. Otherwise, the cooling and heating effects will be seriously impacted, and the compressor may become

burnt.

(2) The gas pipes are cold when the unit operates in cooling mode. If they are not properly insulated, they may cause

condensation and water leakage.

(3) The outlet pipe (gas pipe) is hot (usually 50–100°C) when the unit operates in heating mode, and accidental contact

with the pipe will cause burns. To avoid burns, the pipes should be insulated.

3. Selection of insulation materials for refrigerant piping

Use the closed-cell foam insulation material, which has a flame retardant level of B1 and heat resistance of over 120°C.

4. Thickness of the insulation layer

When the outer diameter d of the copper pipe is not greater than Φ12.7mm, the thickness δ of insulation layer is greater

than 15mm.

When the outer diameter d of the copper pipe is greater than Φ12.7mm, the thickness δ of insulation layer is greater than

20mm.

CAUTION

The above thickness should be increased if the place is hot and humid.

The pipes outdoors should be protected by metal covers to avoid sunlight, rain, weathering, external force or artificial

damage.

5. Installation and insulation tips

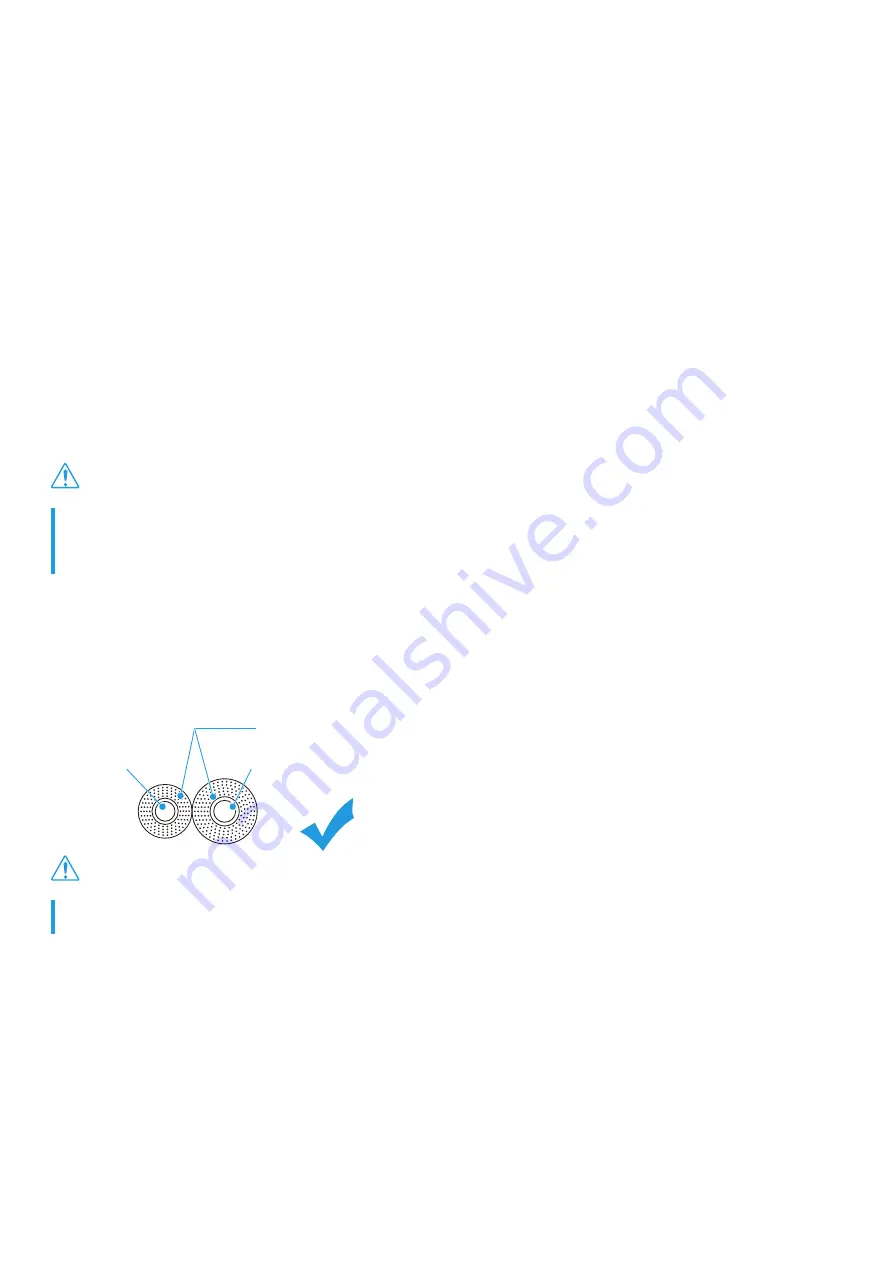

a. Insulate the gas pipe and the liquid pipe separately.

CAUTION

After the gas pipe and the liquid pipe are insulated separately, binding them too tight may damage the insulation

materials already connected.

Liquid pipe

Gas pipe

Heat insulation material