-

5

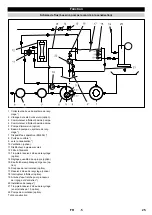

1 Sludge collection of the recycling sys-

tem *)

2 Empty remaining tank content (Option)

3 Float switch, pump basin full (option)

4 Float switch, pump basin empty.

5 Immersion pump (option)

6 Pump basin of the recycling system *)

7 Control shaft *)

8 to drainage system *)

9 Ventilation (option)

10 Multi-channel valve

11 Filament filter

12 Overflow of recycled water tank (option)

13 Fresh water volume settings (option)

14 Freshwater - emergency filling (option)

15 Circulation valve (option)

16 Recycled water tank (option)

17 Float switch (option)

18 Fresh water inlet for rinsing and care

processes *)

19 Washing unit *)

20 Circulation pump (option)

*) on building side

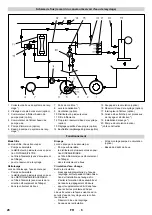

In filter operations, the water flows via

–

Immersion pump

–

multi-channel valve in position FIL-

TERN/FILTER...

–

Filament filter (flow direction of filtering)

–

to the recycled water tank

During backwash, the water flows via

–

Immersion pump

–

multi-channel valve in position RÜCK-

SPÜLEN/BACKWASH...

–

Filament filter (against flow direction of

filtering)

–

To the sludge collector

During final rinse the water flows via

–

Immersion pump

–

Multi-channel valve in position NACH-

SLPÜLEN/RINSE...

–

Filament filter (flow direction of filtering)

–

To the sludge collector

Purpose of circulation:

–

Additional movement of the recycled

water, especially when the washing

system has come to a standstill, to

avoid formation of brackish water and

reducing the odour problem.

–

Additional supply of air to the water to

avoid odour problem

The water flows from the recycled water

tank to the sludge removal as follows:

–

Recycled water tank

–

Circulation valve

–

Upgrade kit circulation pump (option)

–

Sludge removal

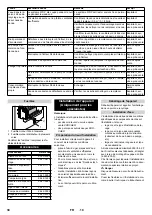

Flow chart (drainage connection on recycled water tank)

Functional description

Filter operations

Backwash

Final rinse

Processed water circulation

16

EN

Summary of Contents for WRP 3000 Comfort

Page 2: ...2 ...