Seite 5 von 20

Operating voltage: 12V car battery, average power consumption: < 7 mA (± 20 %),

Fitted reverse polarity protection, battery monitor: switches off automatically when battery voltage < 11.1 V (± 3 %)

Very simple connection, connection to vehicle terminal 15 no longer required

Ultrasonic frequency approx. 22.5 kHz ± 10% varies randomly in fre rhythm,

Sound pressure: approx. 115 dB ± 25%

Loudspeaker: Fully-encapsulated loudspeaker dome with circular 360˚ sound radiation

Output voltage: approx. 250....300 V =, temperature range: approx. – 25...+ 80 degrees C

Function display: 2 flashing LEDs for ultrasound and high voltage (for scaring and function control)

Dimensions of control device: approx. 86x55x50mm, cable length of high voltage cable: approx. 4 m (± 10 %)

Fuse in fuse holder: Mini 1A (or 2A) blade-type fuse

High-voltage contact pads: 6 sliding cross-shaped stainless-steel contact pads

Also suitable for cars with CAN bus

Automatic reduction of power consumption in the case of short-circuit

or contamination (reactive currents) at the high-voltage pads.

Impulse withstand voltage: max. 40V 2msec

Compact plug-and-socket connection at control device for simple disconnection of the control device from the cable

installation

Licensed with the e1 symbol by the German Federal Motor Transport Authority

Available accessories (not included):

Bonnet switch for immediate discharge, article: 1001

Optionally, the new safety bonnet switch for immediate discharge (article 1001) can be purchased as an accessory.

By using it, the device is not only switched off automatically when the bonnet is opened. At the same time, the

charging capacitor is immediately discharged through the ignition switch; the high voltage is cleared at a stroke.

However, the same can be achieved by actively pulling apart the compact plug-and-socket connection.

Earth mat, article 1003, extends non-conductive floor covering, for example, as an earth surface.

Extension kit, article M4500-K-kit – 4 additional contact pads for large engine compartments

Proper use:

To scare martens and other wildlife from the engine compartments of vehicles using electric shocks, pulsating light and

aggressive, pulsating ultrasonic frequencies.

Disposal:

If the devices have to be disposed of, then they should not be placed with domestic refuse. They must be handed into to

collection points for televisions, computers, etc. (please ask your local authority or town council for the location of these

electronic disposal points).

Ultrasonic sound extends like light; there are “shadows” cast behind obstacles (no ultrasonic sound). The loudspeaker in the

device should therefore radiate towards the areas at risk of being bitten. The ultrasonic sound reaches all points that are

visible from the loudspeaker dome in the engine compartment.

Fitting instructions:

During assembly, please take the fuse of the device from the fuse holder. The base device is installed at a point in the car where it

is not too hot (please don’t install it directly adjacent to the exhaust manifold or other hot area). The positive cable with the fitted

fuse holder is connected to

“+ 12 V”.

The earth cable is connected to the vehicle earth or

“- 12 V”.

Optionally, you can purchase a bonnet switch (no. 1001) as an accessory. This

“short-circuit switch” immediately discharges the

high-voltage pads when the bonnet is opened (for maintenance work). However, you can also take the mini blade-type fuse out of

the fuse holder by hand and then wait approx. 1 minute until the high voltage has dissipated in order to then carry out maintenance

work with the marten scarer switched off. Or you can disconnect the compact plug connection. The marten scarer is then

immediately switched off and the high-voltage pads are voltage free. For this reason, please fit the device so that the plug

connection and fuse holder can be reached easily.

The high-voltage cable is laid in the engine compartment so that the contact pads can be fitted at the points of risk of being bitten.

The high-voltage cable should not be run directly past very hot engine parts (e.g. exhaust manifold) (the cable insulation may melt).

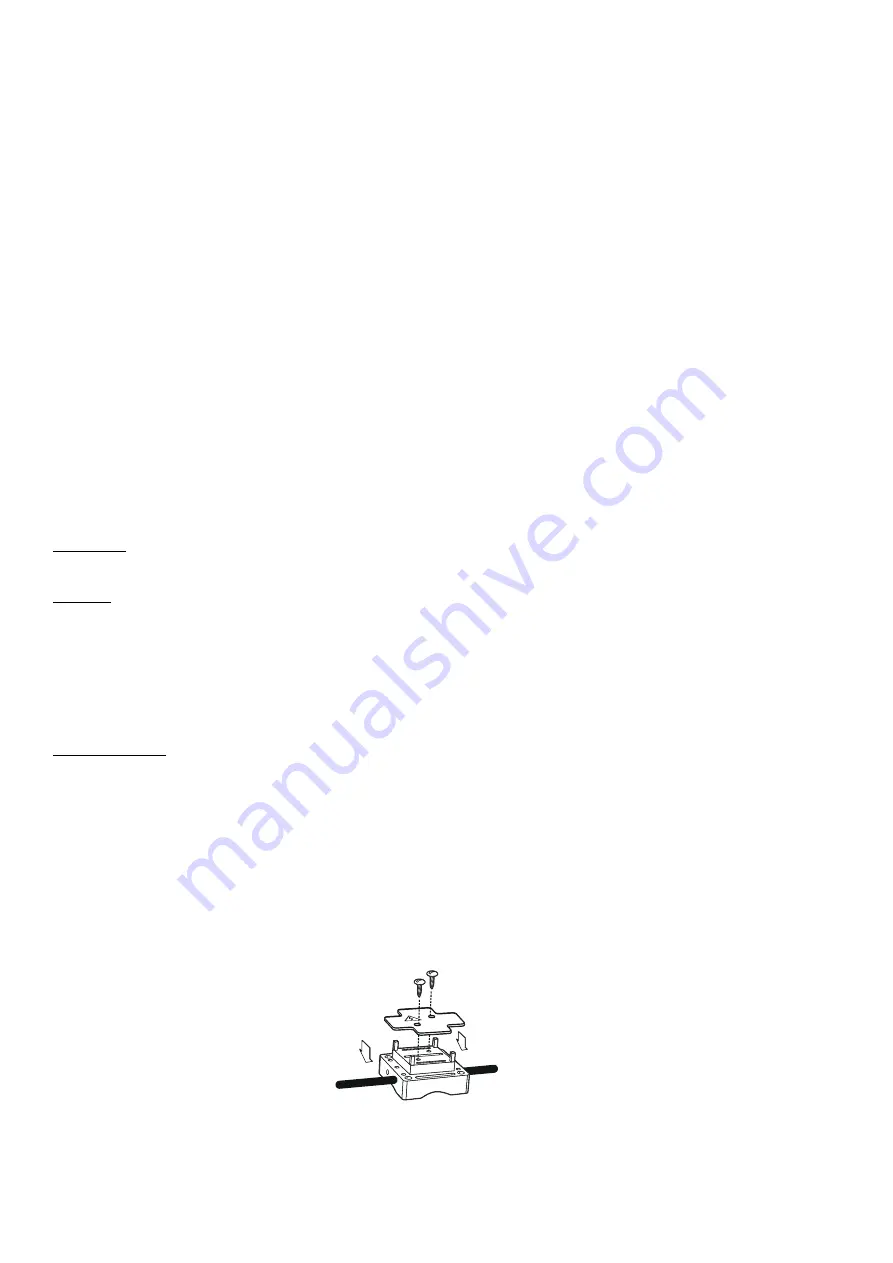

The high-voltage pads can be fitted at any point on the high voltage cable, as shown in the drawing.

The high-voltage cable of the marten scarer is easily identifiable as the longest cable by far (approx. 4 m). The contact pads are

fixed in the engine compartment of the car using the 4 drilled holes in the plastic lower section (using screws or cable ties). The

cross-shaped stainless-steel pads are attached to the plastic holders.

The contact pads are fastened to the plastic holder using two screws. By turning the screw, the high-voltage cable is

“tapped” and

the contact is created. The plastic holders can be moved on the high-voltage cable and can be fixed at any point.