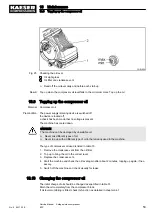

Fig. 22 Air filter maintenance

1

Air filter

2

Inlet air opening

3

Air filter element

4

Retaining clip

5

Cover

1. Unscrew the air filter.

2. Release the retaining clip and take off the cover.

3. Blow out the cover and the insert with dry compressed air (<5 bar).

4. Clean the housing and sealing faces.

5. Wet the wire mesh insert lightly with oil after cleaning.

If the insert is heavily clogged, clean with a solvent-based fluid or steam blaster.

Observe safety regulations.

Replace the air filter if it has already been cleaned a number of times.

6. Position the cover over the insert and close the retaining clips.

7. Mount the air filter again.

The filter air inlet must face downwards.

8. Switch on the power supply disconnecting device.

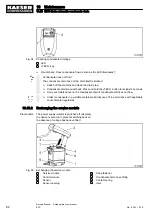

10.5 Option H9

Air filter (noise absorbing) maintenance

Check that all sealing surfaces match each other. The use of an unsuitable air filter element can

permit dirt to ingress the pressure system and cause damage to the machine.

Material Compressed air for blowing out

Spares as required

Precondition The supply disconnecting device is switched off,

the device is locked off,

a check has been made that no voltage is present.

The machine has cooled down.

10 Maintenance

10.5 Air filter (noise absorbing) maintenance

50

Service Manual 2-stage piston compressor

EPC

No.: 9_9431_02 E

Summary of Contents for EPC Series

Page 2: ...Original instructions KKW PEPC 1 04 en SBA KOLBEN ANLAGE 2 STUFIG STERN DREIECK...

Page 6: ...Contents iv Service Manual 2 stage piston compressor EPC No 9_9431_02 E...

Page 8: ...List of Illustrations vi Service Manual 2 stage piston compressor EPC No 9_9431_02 E...

Page 10: ...List of Tables viii Service Manual 2 stage piston compressor EPC No 9_9431_02 E...