8.

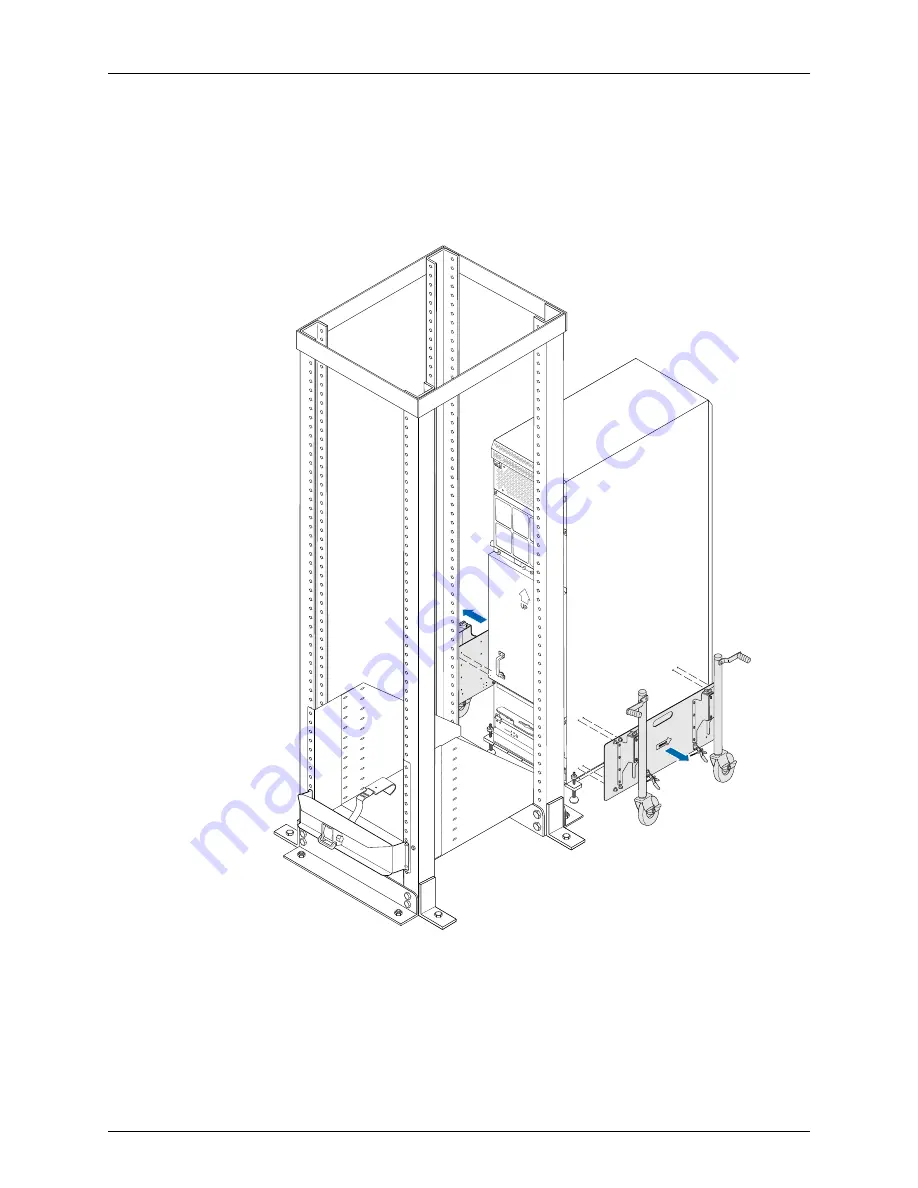

Using a number 3 Phillips screwdriver, loosen the captive screws that secure the router

transport mounting plates and wheel assembly to the chassis, and set them aside

(see

).

Figure 27: Remove Router Transport Mounting Plate and Wheel Assembly

g000065

9.

Attach the winch strap to the winch strap plate at the rear of the router (see

35

Copyright © 2014, Juniper Networks, Inc.

Use the Router Transport Kit to Install the Router in a Four-Post Rack