JRC-Series

R e v. : D e c e m b e r 8 , 2 0 2 1

T H E S M A R T S O L U T I O N F O R E N E R G Y E F F I C I E N C Y

I n s t a l l a t i o n , O p e r a t i o n , M a i n t e n a n c e

17

Water Quality Standards, Cont’d.

1. The Water Quality Table provides water quality

requirements for coaxial & brazed plate heat

exchangers.

2. The water must be evaluated by an independent

testing facility comparing site samples against

this Table. When water properties are outside of

these parameters, the water must either be treated

by a professional water treatment specialist to

bring the water quality within the boundaries of

this specification, or an external secondary heat

exchanger must be used to isolate the heat pump

water system from the unsuitable water. Failure to

do so will void the warranty of the heat pump system

and will limit liability for damage caused by leaks or

system failure.

3. Regular sampling, testing and treatment of the water

is necessary to assure that the water quality remains

within acceptable levels thereby allowing the heat

pump to operate at optimum levels.

4.

If closed‐loop systems are turned off for extended

periods, water samples must be tested prior to

operating the system.

5. For optimal performance, it is recommended that the

closed‐loop piping systems are initially filled with de‐

ionized water.

6. Well water with chemistry outside of these

boundaries, and salt water or brackish water requires

an external secondary heat exchanger. Surface/Pond

water should not be used.

7. If water temperature is expected to fall below 40°F,

antifreeze is required. Refer to the heat pump IOM for

the correct solution ratios to prevent freezing.

α

Hydrogen Sulfide has an odor of rotten eggs. If one

detects this smell, a test for H2S must be performed.

If H2S is detected above the limit indicated,

remediation is necessary (Consult with your Water

Testing/Treatment Professional) or a secondary heat

exchanger is required using appropriate materials as

recommended by the heat exchanger supplier.

β

Suspended solids and particulates must be filtered

to prevent fouling and failure of heat exchangers.

Strainers or particulate filters must be installed to

provide a maximum particle size of 600 micron (0.60

mm, 0.023 in.) using a 20 to 30 mesh screen size.

When a loop is installed in areas with fine material

such as sand or clay, further filtration is required to a

maximum of 100 micron. Refer to the Strainer / Filter

Sizing Chart to capture the particle sizes encountered

on the site.

χ

An electrical grounding system using a dedicated

ground rod meeting NEC and Local Electrical

codes must be installed. Building Ground must not

be connected the WSHP piping system or other

plumbing pipes.

δ

Refer to IOM for instructions on measuring resistance

and leakage currents within water loops.

Do not use PVC pipe for water loop (compressor POE

oil and glycols damage PVC) use of HDPE pipe is

recommended.

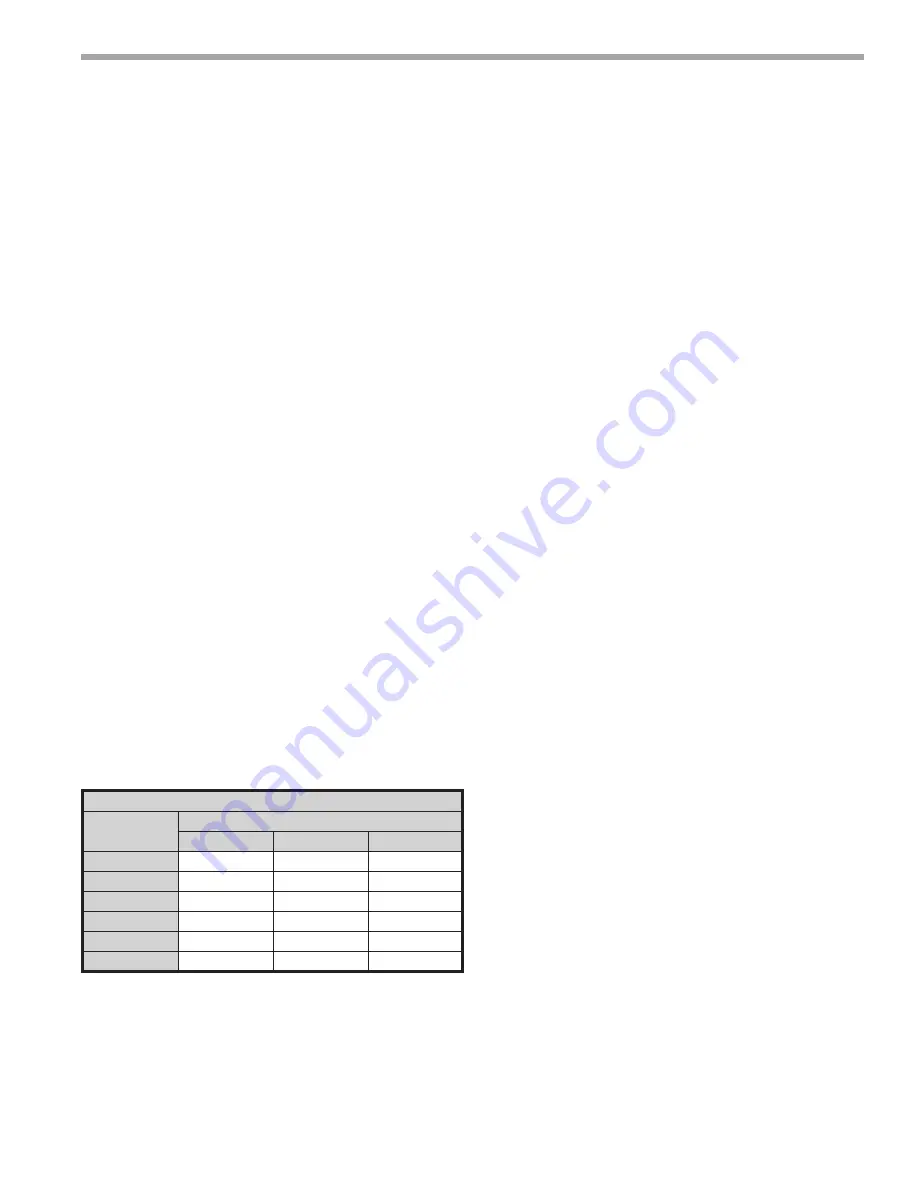

Strainer / Filter Sizing

Mesh Size

Particle Size

Microns

MM

Inch

20

840

0.840

0.0340

30

533

0.533

0.0210

60

250

0.250

0.0100

100

149

0.149

0.0060

150

100

0.100

0.0040

200

74

0.074

0.0029

ppm = parts per million

ppb = parts per billion