6052931-UAI-A-0121

Johnson Controls Ducted Systems

7

Line power connections

Power can be brought into the air handler through the outlet air

end of the unit (top left when the unit is vertical) or the left-side

panel. For the residential packaged unit, power can be brought

into the electric/controls area through the power supply provi-

sions in the bottom or right side of the unit. To minimize air leak-

age for any unit, seal the field wiring entry point.

Field wiring connects to electric heat kits with service discon-

nect or terminal block depending on the electric heat kit model.

The multiple circuit, single-phase electric heat kits have options

for a single power supply. For the 3 phase 20 kW and 25 kW

electric heat kits with multiple circuits, a single-point power

accessory kit can be ordered separately. A ground lug is pro-

vided on the kits. Refer to the unit installation instructions for

electrical specifications. See Figure 6 and Figure 7.

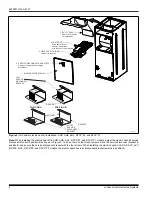

Figure 6:

Electric heat kit connection

FACTORY WIRING

Attached to this side -

no need for removal.

TERMINAL BLOCK OR

SERVICE DISCONNECTS

May have 1, 2, or 3 service disconnects.

FIELD SUPPLIED WIRING

Attaches to left side.

A0241-001

Figure 7:

Air handler and residential packaged unit electric heat power

),(/'32:(5:,5,1*

9WKUX9RU9

&20321(17&2'(6

*1'*5281'/8*

6'6(59,&(',6&211(&7

&.7&,5&8,7

*1'

-803(5%$5

6,1*/(6285&(32:(5

08/7,6285&(32:(5

6,1*/(6285&(32:(5

:,7+-803(5%$5

6'

32:(5

6833/<

/

/

7(50,1$/%/2&.25

6(59,&(',6&211(&7

32:(5

6833/<

*1'

/

/

6,1*/(6285&(32:(5

7(50,1$/%/2&.25

6(59,&(',6&211(&7

*1'

32:(5

6833/<

/

/

/

&.7

&.7

32:(5

6833/<

6'

6'

*1'

/

/

/

/

/

/

08/7,6285&(32:(5

32:(5

6833/<

&,5&8,7621.:.:

&,5&8,7621.:

*1'

/

/

/

/

/

/

&.7

6'

6'

6'

&.7

&.7

&,5&8,7621.:.:

&,5&8,7621.:

6,1*/(3+$6((/(&75,&+($7237,216

7+5((3+$6((/(&75,&+($732:(5237,216

$

6,1*/(6285&(32:(5

:,7+6,1*/(32,17

32:(5$&&(6625<

32:(5

6833/<

6'

*1'

/

/

/

/

/

/

6'

/

/

/

6'

6'