6052931-UAI-A-0121

Johnson Controls Ducted Systems

3

6.

Install the electric heat kit as follows:

a.

Position and insert the electric heat kit into the opening

in the air handler unit.

b.

Align the mount holes and fasten the electric heat kit to

the air handler unit with four duct cover screws.

7.

Remove and discard the air handler power connection wir-

ing that is for use without electric heat (the connector con-

taining only the red and black wires) from the 6-pin

connector.

8.

Connect the 6-pin socket connector of the electric heat kit

to the control/power 6-pin connector in the air handler. The

end terminals are D-shaped to ensure polarization of the

connector.

9.

Mark an X in the appropriate box on the indoor unit rating

plate for the particular electric heat kit installed.

10. Refer to the unit rating plate for the minimum blower speed

required for the electric heat kit model installed, and set the

blower speed accordingly.

CAUTION

To prevent damage, carefully pass the accessory heating ele-

ment through the rectangular opening in the discharge duct.

Element mounting plate must be secured with four screws.

!

WARNING

Verify edges of foil faced insulation are not in contact with any

exposed electrical connections.

NOTICE

All wiring must comply with local and National Electrical Code

requirements. Read and heed all unit caution labels.

NOTICE

An optional service disconnect cover can be applied to seal/

protect the Service Disconnects (S1-02435672000).

!

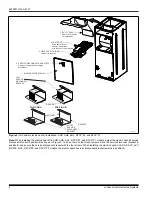

Figure 2:

Typical electric heat kit installations - air handler

UPFLOW

HORIZONTAL RIGHT

HORIZONTAL LEFT

HEAT

HEA

T

HEA

T

DOWNFLOW

HEAT

A0330-001