175619-XIM-C-0109

Johnson Controls Unitary Products

13

ECONOMIZER/MOTORIZED DAMPER AND RAIN HOOD

The instruction for the optional economizer/motorized

damper and rain hood can be found in form 035-

07364-000. Use these instructions when field assem-

bling an economizer rain hood onto a unit. The outdoor

and return air dampers, the damper actuator, the

damper linkage, the outdoor and return air divider baf-

fles, and all the control sensors are factory mounted as

part of the “Factory installed” economizer/motorized

damper options.

POWER EXHAUST/BAROMETRIC RELIEF DAMPER AND

RAIN HOOD

The instructions for the power exhaust/barometric relief

damper and rain hood can be found in form 530.18-

N1.10V.

All of the components, including the dampers, hard-

ware, and mounting instructions are shipped in a single

package external from the unit, and must be field

assembled and installed.

Power exhaust is only available as a field installed

accessory.

ECONOMIZER AND POWER EXHAUST DAMPER

SET POINT ADJUSTMENTS AND INFORMATION

Remove the economizer access panel from the unit.

Loosen but do not remove the two panel latches.

Locate the economizer control module, where the fol-

lowing adjustments will be made.

Check that the damper blades move smoothly without

binding; carefully turn the Minimum Position Adjusting

screw (found on the damper control module) fully

clockwise and then set the thermostat indoor fan switch

to the on position and then off, or energize and de-

energize terminals “R” to “G”.

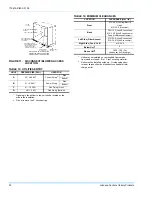

MINIMUM POSITION ADJUSTMENT

With thermostat set to indoor fan on position, or termi-

nals “R” to “G” energized, turn the Minimum Position

Adjusting screw (located on the damper control mod-

ule) counterclockwise until the desired minimum

damper position has been attained.

ENTHALPY SET POINT ADJUSTMENT

The enthalpy set point may now be set by selecting the

desired setpoint shown in the Enthalpy Setpoint Adjust-

ment Figure 4. Adjust as follows:

•

For a single enthalpy operation carefully turn the

set point adjusting screw (found on the damper

control module) to the “A”, “B”, “C” or “D” setting

corresponding to the lettered curve of the Enthalpy

Setpoint Adjustment Figure 4.

•

For a dual enthalpy operation, carefully turn the set

point adjusting screw fully clockwise past the “D”

setting.

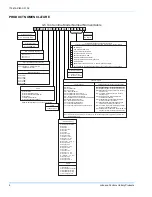

TABLE 3: ELECTRIC HEATER SUPPLY AIRFLOW LIMITATIONS

7

10

15

20

30

M

3

/S

0.47

0.57

0.57

0.61

-

CFM

1100

1200

1200

1300

-

M

3

/S

0.61

0.61

0.61

0.61

-

CFM

1300

1300

1300

1300

-

M

3

/S

0.75

0.75

0.75

0.75

0.75

CFM

1600

1600

1600

1600

1600

HEATER SIZE NOMINAL KW

MINIMUM

SUPPLY AIR

VOLTAGE

UNIT MODEL SIZE

NOMINAL TONS

3

4

5

380/415-3-50

380/415-3-50

380/415-3-50

Extreme care must be exercised in turning all

setpoint, maximum, and minimum damper

positioning adjustment screws to prevent twist-

ing them off.