EN-13

2.0-2

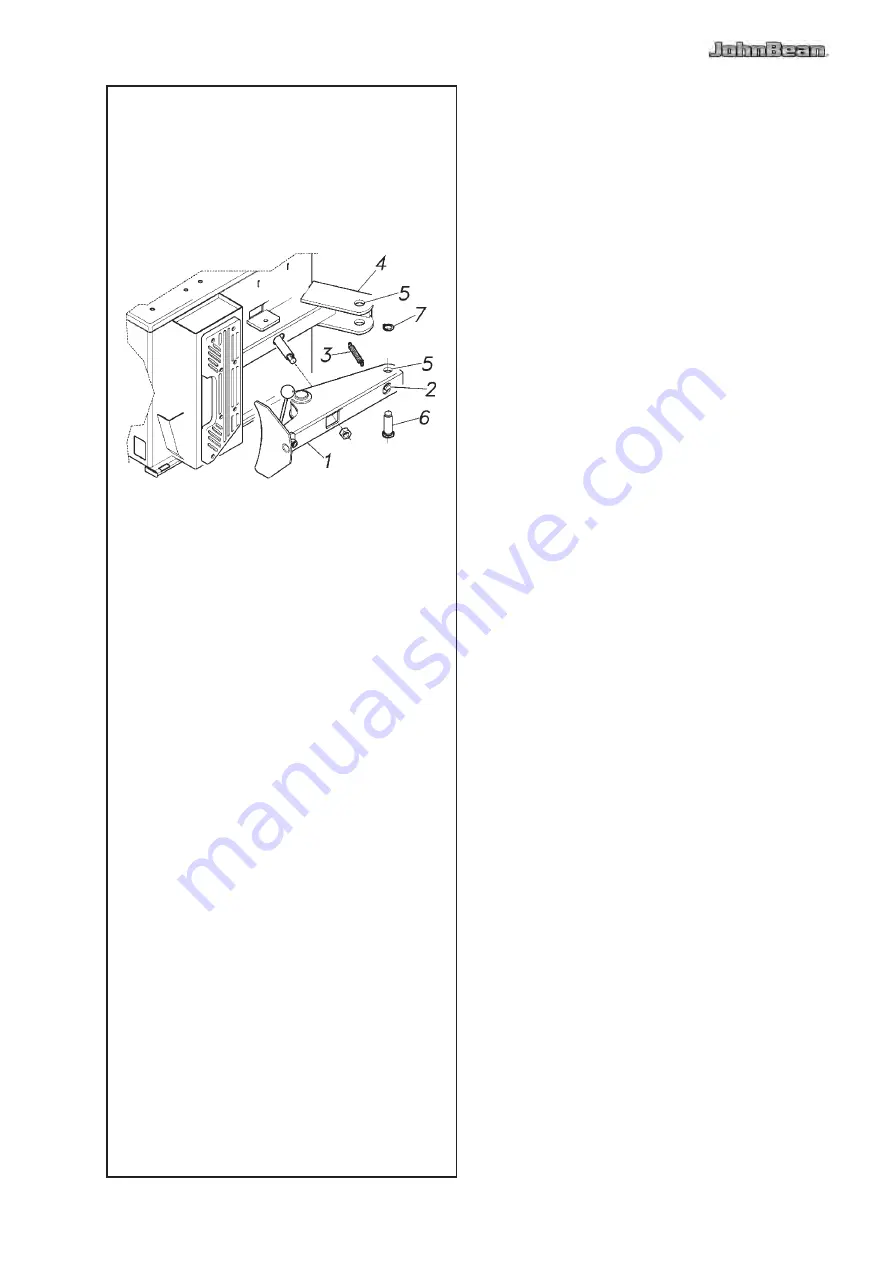

2.2 bEAD bREAKER INSTAllATION

Sometimes the side mounted Bead Breaker is shipped

from the factory dismounted for a more compact

shipping package.

A.

Cut the plastic tie strap which secures the Breaker

Arm to the cabinet pivot.

b.

Place the bead breaker arm (1,Fig.

2.0-2

) inside

arm support (4). Holes (5) of the bead breaker arm and

of the arm support must match. Grease pin (6). Lock

arm (1) to support (4) with pin (6) and ring (7).

C.

Attach spring (3,Fig.

2.0-2

) to the hook on the frame

and attach it to hook (2) on bead breaker arm.

TIP:

You may tie a small rope or cord onto the free

end of the spring, run the cord through the hole. Pull the

spring end toward the split pin and loop free end over.

2.3 AIR INSTAllATION

WARNING!

THE AIR INSTAllATION MUST bE MADE ONlY bY

lICENSED PERSONNEl.

WARNING!

EXCESSIVE AIR PRESSURE CAN SERIOUSlY

INJURE PERSONNEl AND DAMAGE THE MACHINE.

Ensure that the line pressure is within the limits

required by the machine. If the pressure exceeds

170 psi (12 bar) it is mandatory to install a pressure

regulator before the air inlet of the machine.

If the air pressure is lower than the minimum required

of 110 psi (8 bar) the clamping power of the turntable

and the bead breaker power may be insufficient for

certain tires and substantially reduces tire changer

performance.

It is suggested that the air supply be equipped with a

water separator/dryer type modification for maximum

performance.

After ensuring all the above proceed as follows: