11.0 FINAL CHECK OF ASSEMBLED LIFT

1. Check for air and hydraulic leaks. ___

2. Ensure all safety lock mechanisms are working correctly. ___

3. Check all fasteners, tighten if necessary. ___

4. Operate lift to full stroke then lower to ground while checking for proper

functionality. ___

5. Ensure Customer Care Kit is complete and given to operator. ___

a. Operation Manual ___

b. ANSI / ALI Lift It Right Manual ___

c. ANSI / ALI Safety Tip Card ___

d. ANSI / ALI ALIS Safety Requirements for Installation and Service

of Automotive Lifts ___

e. ANSI / ALI Quick Reference Guide ___

6. Train end user on operation of the lift. ___

18

Summary of Contents for 40HP210ES

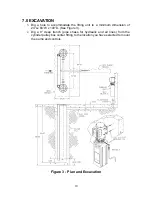

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

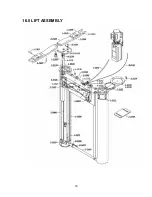

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

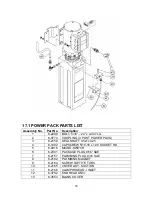

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...