Figure 9 - INCORRECT positioning of flip pad adapters

Lifting:

1. Push in on “pump electrical switch” and raise lift until adapters contact

vehicle.

2. Check to make certain that all height adapters are making full and proper

contact and are stable.

3. Raise lift approximately 18” and check stability by rocking vehicle front to

rear.

4. While raising the lift, the air lift safety locks will engage at different stages.

Raise lift to desired height and lower onto lift locks. Avoid sporadic starting

and stopping of pump motor if possible.

5. To prevent pump motor damage, always lower load onto safety locks

when restarting motor in mid-stroke.

Lowering:

1. Make sure area under vehicle is clear of obstacles.

2. Raise lift slightly.

3. To disengage air-operated lift safety locks, push air lock release button in

while pushing on handle to lower the lift.

4. Lower the lift until lift superstructures make full contact with floor.

5. Rotate arms to provide tire clearance.

6. Make certain adapters are in the flat position before removing vehicle.

NOTE: Remove 8-7/8” Truck Height Adapters, if used.

20

Summary of Contents for 40HP210ES

Page 9: ...Figure 1 Bay Layout Option A 8 ...

Page 10: ...Figure 2 Bay Layout Option B 9 ...

Page 12: ...Figure 4 Elevation 11 ...

Page 14: ...Figure 5 Cable Routing 13 ...

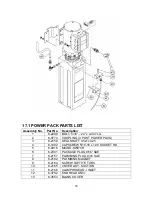

Page 15: ...Figure 6 Hydraulic and Air Connections 14 ...

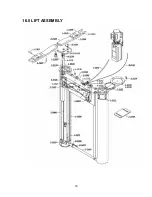

Page 25: ...16 0 LIFT ASSEMBLY 24 ...

Page 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Page 28: ...17 0 POWER PACK ASSEMBLY 27 ...