SECTION 4 - BASE COMPONENTS

3121222

– JLG Lift –

4-3

4.3

WHEELS AND TIRES - DRIVE AND REAR

Tire Wear and Damage

Inspect tires periodically for wear or damage. Tires with

worn edges or distorted profiles require replacement.

Tires with significant damage in the tread area or side wall,

require immediate evaluation before replacing the

machine into service.

Wheel and Tire Replacement

Replacement wheels must have the same diameter and

profile as the original. Replacement tires must be the same

size and rating as the tire being replaced.

Wheel Installation

It is extremely important to apply and maintain proper

wheel mounting torque.

WHEEL LUG NUTS MUST BE INSTALLED AND MAINTAINED AT THE

PROPER TORQUE TO PREVENT LOOSE WHEELS, BROKEN LUG NUTS,

AND POSSIBLE SEPARATION OF WHEEL FROM THE AXLE. BE SURE TO

USE ONLY THE LUG NUTS MATCHED TO THE CONE ANGLE OF THE

WHEEL.

Tighten the lug nuts to the proper torque to prevent

wheels from coming loose. Use a torque wrench to tighten

the fasteners. If you do not have a torque wrench, tighten

the fasteners with a lug wrench, then immediately have a

service garage or dealer tighten the lug nuts to the proper

torque. Over-tightening will result in breaking the lug nuts

or permanently deforming the mounting holes in the

wheels. The proper procedure for attaching wheels is as

follows:

1.

Start all lug nuts by hand to prevent cross

threading. DO NOT use a lubricant on threads or

nuts.

2.

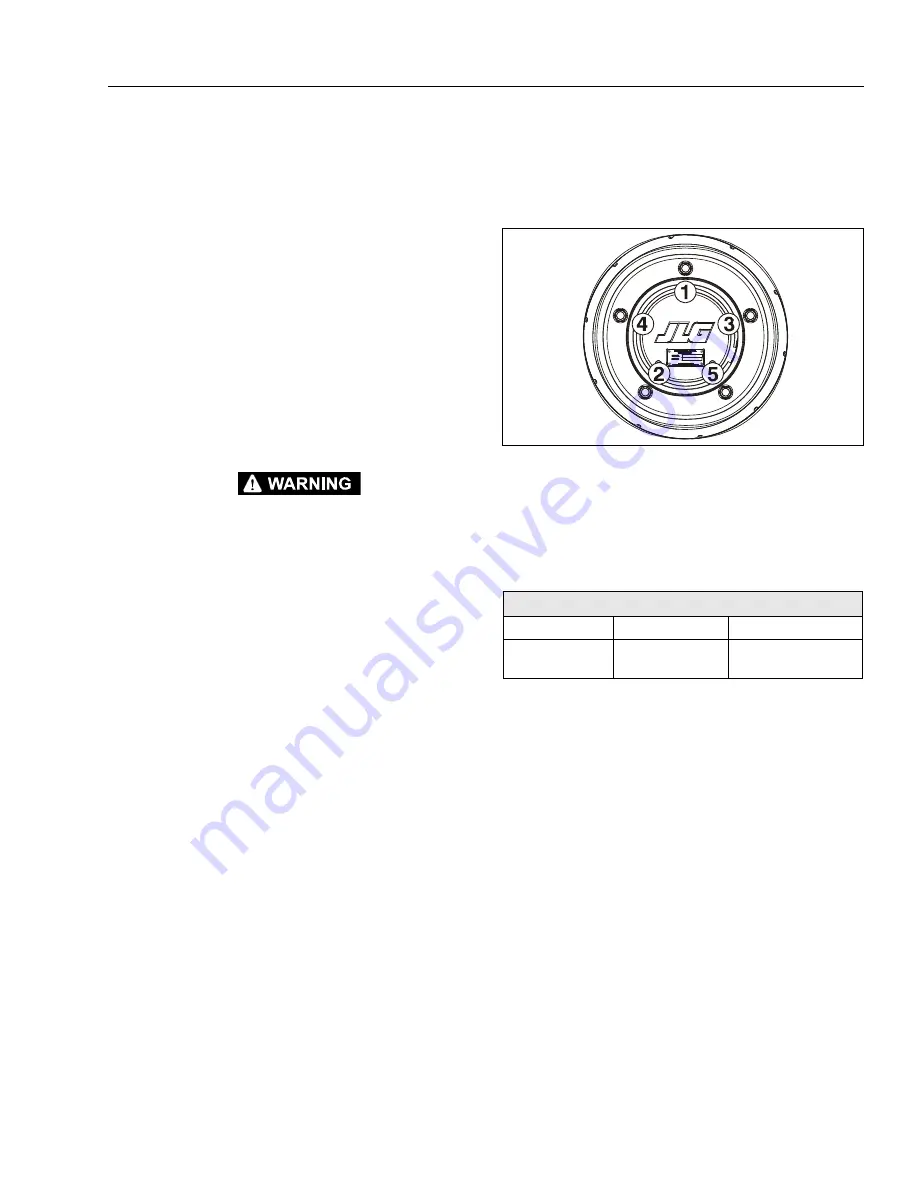

Tighten lug nuts in the following sequence.

3.

The tightening of the lug nuts should be done in

stages. Following the recommended sequence,

tighten lug nuts per wheel torque.

4.

Wheel lug nuts should be torqued after the first

50 hours of operation and after each wheel

removal. Check torque every 3 months or 150

hours of operation.

Figure 4-2. Wheel Lug Nut Tightening Sequence

Table 4-1. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

20-30 ft lbs

(28 - 42 Nm)

65-80 ft lbs

(91 - 112 Nm)

105 -120 ft lbs

(142 - 163 Nm)

Summary of Contents for 1230ES

Page 1: ...AS NZS Service and Maintenance Manual Model s 1230ES P N 3121222 June 22 2017 ...

Page 2: ...NOTES ...

Page 24: ...SECTION 1 MACHINE SPECIFICATIONS 1 12 JLG Lift 3121222 NOTES ...

Page 32: ...SECTION 2 GENERAL SERVICE INFORMATION 2 8 JLG Lift 3121222 NOTES ...

Page 78: ...SECTION 4 BASE COMPONENTS 4 40 JLG Lift 3121222 NOTES ...

Page 104: ...SECTION 5 CONTROL COMPONENTS 5 26 JLG Lift 3121222 NOTES ...

Page 158: ...SECTION 8 DIAGNOSTIC TROUBLE CODES 8 22 JLG Lift 3121222 NOTES ...

Page 198: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 40 JLG Lift 3121222 ...

Page 199: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 3121222 JLG Lift 9 41 ...

Page 200: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 42 JLG Lift 3121222 ...

Page 202: ...SECTION 9 GENERAL ELECTRICAL INFORMATION SCHEMATICS 9 44 JLG Lift 3121222 NOTES ...