34

Gangway16 Operation

When Gangway16 Operation is enabled in the menu, the ES-

SloMo is able to remotely control the Gangway16. The ES-SloMo

must have version 1.23 or later firmware to control the

Gangway16. The Gangway16 requires version 1.01 firmware or

later to be controlled by the ES-SloMo.

Firmware upgrades are available for purchase from the

JLCooper Electronics Service Department. You can contact the

Service Department by dialing (310) 322-9990 in North America

or +1-310-322-9990 outside North America. The Service

Department is also available by email at: [email protected].

Setup

To use the Gangway16 with the ES-SloMo:

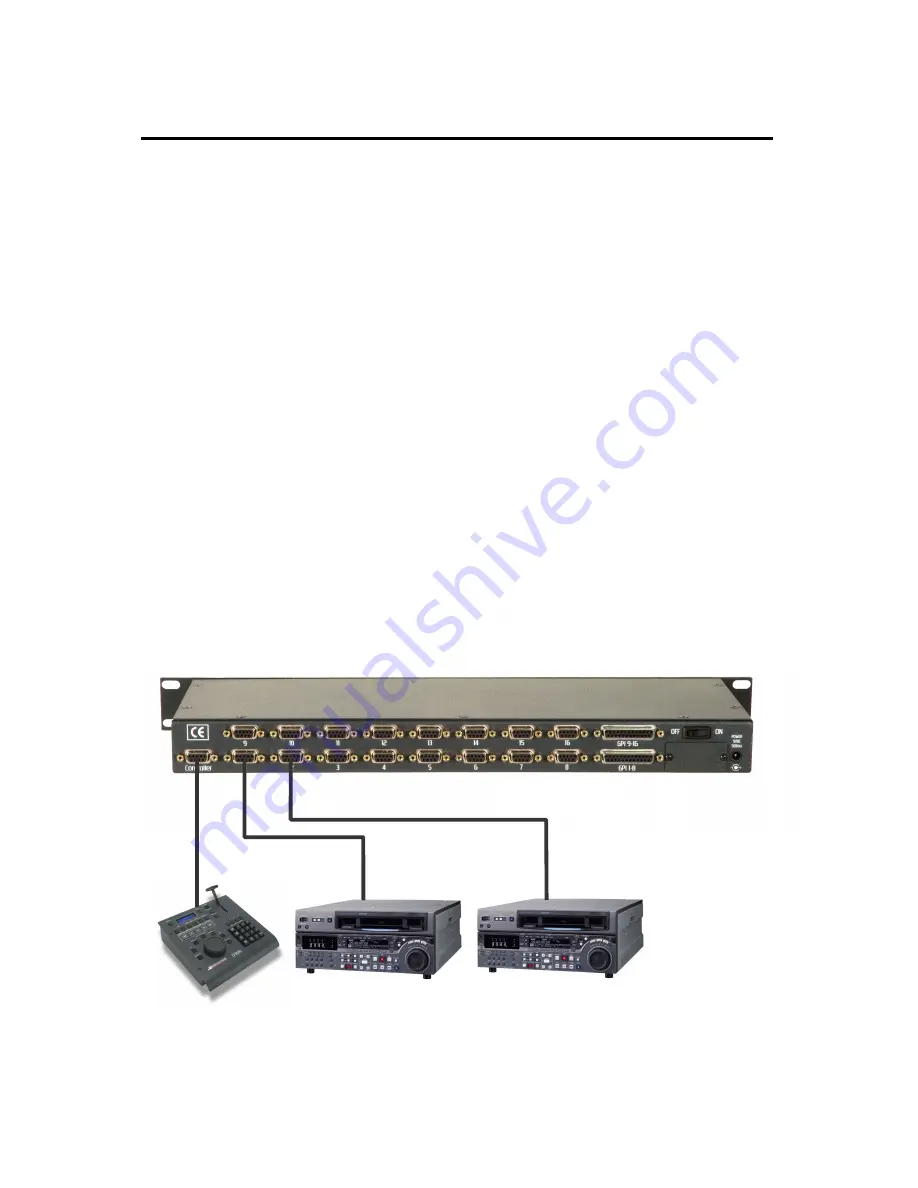

1. Connect port 1 of the ES-SloMo to the rear panel controller

port of the Gangway16 as shown below.