5

22. Maintain a balanced stance at all times so that

you do not fall into the blade or other moving

parts. Do not overreach or use excessive force

to perform any machine operation.

23. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a

job for which it was not designed. The right tool

will do the job better and more safely.

24.

Use recommended accessories; improper

accessories may be hazardous.

25. Maintain tools with care. Follow instructions for

lubricating and changing accessories.

26. Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. Table 2

(see sect. 7.3)

shows

correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the gage

number, the heavier the cord.

27. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use your hands.

28. Do not stand on the machine. Serious injury

could occur if the machine tips over.

29. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

30. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

31. Don’t use in dangerous environment. Don’t use

power tools in damp or wet location, or expose

them to rain. Keep work area well lighted.

32. Hold workpiece down against table firmly at all

times.

33. Do not sand workpieces that are too small to be

safely supported.

34. Always use appropriate table insert for the

selected spindle or drum. Do not sand without a

table insert in place.

35. Allow machine to reach operating speed before

beginning to sand.

36. Do not operate this sander with a damaged

spindle or sanding sleeve.

37. Always feed work against direction of spindle

rotation.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

SAVE THESE INSTRUCTIONS

4.0

About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for the JET Model

JOSS-S Oscillating Spindle Sander. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide consistent, long-term operation if used in accordance with the instructions as set forth in

this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

Summary of Contents for JOSS-S

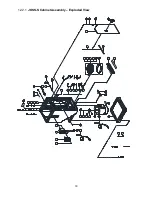

Page 15: ...15 12 1 1 JOSS S Table Assembly Exploded View...

Page 18: ...18 12 2 1 JOSS S Cabinet Assembly Exploded View...

Page 20: ...20 12 3 1 JOSS S Spindle and Drum Assembly Exploded View...

Page 23: ...23 13 0 Electrical Connections JOSS S Spindle Sander...

Page 24: ...24 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...