12

8.2

Table tilt for bevel sanding

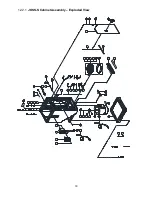

Refer to Figures 11 and 12.

1. Loosen both knobs (A, Figure 11)

counterclockwise.

To tilt forward (45-degree maximum):

2. Move table by hand to desired angle shown on

scale (B). Scale is marked in 5-degree

increments.

3. Retighten knobs (A).

To tilt backward (15-degree maximum):

4. Pull out pin (C) and rotate it 90-degrees to keep

it disengaged.

5. Tilt table to desired position, and tighten knobs

(A).

Figure 11: table tilt

Figure 12: table tilt

8.2.1

Setting 90- and 45-degree stops

Tools required

:

machinist square

13mm wrench

Refer to Figures 11 through 13.

1. Make sure table insert has been leveled with

table

(sect. 6.7).

2. Make sure pin (C) is re-engaged to contact stop

screw. Position table at zero (90-degrees)

against stop screw (D).

3. Place square on table and against front of drum

or spindle (Figure 13).

4. Rotate screw (D) until square sits flush against

table and spindle/drum.

5. If needed, loosen pointer (E) and align it with

zero degree mark.

6. Tilt table to 45-degrees and check accuracy of

45-degree stop screw (F). Adjust as needed.

Note: The above procedure is sufficient for most

wood sanding operations. If greater angle precision

is needed, remove insert and use a larger square

flush against a bare spindle and table surface to set

90-degree stop.

Figure 13: setting tilt stop

9.0

Operations

9.1

Operating guidelines

1. Select spindle that is slightly smaller than curve

to be sanded.

2. Make sure spindle is properly secured on main

shaft.

3. Use table insert that has smallest opening

possible without contacting sanding sleeve.

4. Loosen both table handles and position table at

desired angle. Tighten both table handles

before operating.

5. Turn on sander and allow it to reach full speed

before starting work.

6. Hold workpiece firmly and against table at all

times.

7. For best results, keep workpiece moving

against spindle.

8. When table is at zero (90-degrees), workpiece

may approach sanding sleeve from any part of

table. When table is tilted, use table area in front

of spindle.

Summary of Contents for JOSS-S

Page 15: ...15 12 1 1 JOSS S Table Assembly Exploded View...

Page 18: ...18 12 2 1 JOSS S Cabinet Assembly Exploded View...

Page 20: ...20 12 3 1 JOSS S Spindle and Drum Assembly Exploded View...

Page 23: ...23 13 0 Electrical Connections JOSS S Spindle Sander...

Page 24: ...24 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...