10

Note: Leveling one insert is sufficient as all

inserts are same thickness.

Figure 6: mounting table insert

6.8

Wrench storage

The provided combination wrench has a magnetic

strip, and can be placed against any metal surface.

Expose the adhesive on the additional magnetic

strip and apply anywhere on the cabinet surface.

The hex key can be stored against it.

6.9

Dust collection

A sander produces a significant volume of wood

dust; the use of a dust collection system is strongly

recommended. It will help keep the shop clean, as

well as reduce potential health hazards caused by

inhalation of wood dust. The collector should have a

capacity sufficient for this size machine; minimum

300 CFM is recommended.

JET has a line of dust collection systems available;

see your dealer or visit our website listed on the

cover.

Connect the hose of your dust collection system to

the 4-inch dust port (Figure 7) at rear of sander.

Secure tightly with a hose clamp.

Figure 7

7.0

Electrical connections

The JOSS-S sander is rated at 115/230V power,

and is pre-wired for 115 volt. The sander comes with

a plug designed for use on a circuit with a

grounded

outlet

that looks like the one pictured in

A

, Figure 8.

Before connecting to power source, be sure switch

is in

off

position.

It is recommended that the JOSS-S sander be

connected to a dedicated 15 amp circuit with a 15

amp circuit breaker or time-delay fuse marked “D”.

Local codes take precedence over recommend-

ations.

7.1

Grounding instructions

1. All Grounded, Cord-connected Tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service pe

r

sonnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause serious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating less than

150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in

A,

Figure

8. An adapter, shown in

B

and

C

, may be used to

connect this plug to a 2-pole receptacle as shown in

B

if a properly grounded outlet is not available.

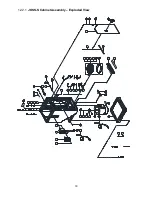

Summary of Contents for JOSS-S

Page 15: ...15 12 1 1 JOSS S Table Assembly Exploded View...

Page 18: ...18 12 2 1 JOSS S Cabinet Assembly Exploded View...

Page 20: ...20 12 3 1 JOSS S Spindle and Drum Assembly Exploded View...

Page 23: ...23 13 0 Electrical Connections JOSS S Spindle Sander...

Page 24: ...24 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...