#1 NEVER PLACE THE OUTFEED STOCK GUIDE ON THE SIDE OF THE CUT OPPOSITE TO

THE FENCE. YOUR STOCK GUIDES STEER THE STOCK INTO THE FENCE AND IF THE

OUTFEED GUIDE WAS PLACED ON THE OPPOSITE SIDE OF THE CUT TO THE FENCE, IT

WOULD EFFECTIVELY STEER YOUR WORK INTO THE BLADE CAUSING IT TO BIND ON

THE BLADE AND POSSIBLY CREATING A DANGEROUS SITUATION WHERE THE STOCK

COULD KICK BACK TOWARD THE OPERATOR!

#2 ALWAYS ENSURE THE STOCK GUIDES WILL NOT CONTACT THE BLADE THOUGHOUT

THEIR ADJUSTMENT UP AND DOWN. WE RECOMMEND THAT THE STOCK GUIDES ARE

ALWAYS AT A MINIMUM 2 INCHES FROM CONTACTING THE BLADE. THE INFEED STOCK

GUIDE SHOULD BE 2 INCHES TOWARD THE FRONT OF THE SAW AWAY FROM THE BLADE

AND THE OUTFEED SHOULD BE 2 INCHES TOWARD THE BACK OF THE SAW AWAY FROM

THE BLADE!

#3 ALWAYS ENSURE THE TRACK KNOBS AND THE CLAMPING KNOB IS SECURELY

TIGHTENED BEFORE TURNING ON THE SAW. ONCE THESE KNOBS ARE SECURED WE

ADVISE LIFTING THE STOCK GUIDE ARM UP AGAINST THE SPRING PRESSURE TO ENSURE

IT IS LOCKED IN THIS POSITION. YOU SHOULD NOT BE ABLE TO MOVE THE

ADJUSTMENT OF THE STOCK GUIDE ARM WITH A REASONABLE AMOUNT OF FORCE.

#4 ALWAYS HAVE NECESSARY SAFETY DEVICES LIKE A PUSH STICK CLOSE AT HAND

WHEN STARTING YOUR CUT TO ENSURE YOU CAN COMPLETE YOUR CUT IN ONE GO

AND TO ENSURE YOU DO NOT PUT YOUR HANDS UNCOMFORTABLY CLOSE TO THE

ROTATING BLADE.

#5 ALWAYS OPERATE YOUR SAW WITH THE PROPER SAFETY GUARDING IN PLACE OR

WITH A RIVING KNIFE IF YOUR SAW HAS ONE. YOUR STOCK GUIDES ARE DESIGNED TO

PROVIDE ADDITIONAL SAFETY AND QUALITY OF YOUR WORK BUT ARE NOT DESIGNED

TO REPLACE THE SAFETY EQUIPMENT THAT CAME WITH YOUR SAW.

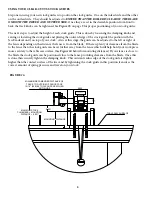

#6 YOUR STOCK GUIDES ARE DESIGNED TO MINIMIZE THE RISK OF KICK BACK FROM

YOUR SAW WHEN USED PROPERLY. TO HELP PREVENT KICK BACK THEY ARE EQUIPPED

WITH ONE WAY BEARINGS TO RESIST TRAVEL TOWARD THE OPERATOR. IN THE EVENT

THAT YOUR STOCK DOES MOVE BACKWARD THE ROLLER WILL NOT SPIN IN THIS

DIRECTION AND THE ROLLER ARM WILL PIVOT DOWN SLIGHTLY APPLYING MORE

PRESSURE TO THE TIRES. IT IS RECOMMENDED TO ADJUST THE LENGTH OF THE PIVOT

ARM SO THAT IT IS AT ROUGHLY A 30 DEGREE ANGLE WHEN IT IS TOUCHING YOUR

TABLE SURFACE OR JUST ABOVE YOUR TABLE SURFACE. IF IT IS SET AT AN ANGLE LESS

THAN THIS THEY WILL STILL FUNCTION PROPERLY BUT WILL APPLY MORE UPWARD

PRESSURE TO YOUR FENCE AND MAY CAUSE YOUR FENCE TO LIFT SLIGHTLY OFF THE

TABLE SURFACE.

THERE ARE A FEW

VERY IMPORTANT POINTS TO REMEMBER

WHEN ADJUSTING YOUR STOCK GUIDES INTO POSITION.

2.