Step one in using your new stock guides is to position the stock guides. One on the infeed side and the other

on the outfeed side. They should be adjusted to

ENSURE THAT THE ROLLER IS CLEAR OF THE BLADE

ON BOTH THE INFEED AND OUTFEED SIDE.

Once they are set in the desirable position from front to

back the track knobs can be tightened. See

Figure #5

on page 9 for proper positioning of your stock guides.

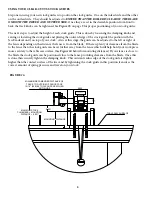

The next step is to adjust the height of each stock guide. This is done by loosening the clamping knob and

raising or lowering the stock guide and placing the outward edge of the stock guide (the portion with the

JessEm decal on it) on top of your stock. Also, at this stage, the guide can be adjusted to the left or right of

the fence depending on the distance the fence is from the blade. If there is plenty of clearance from the blade

to the fence then the stock guide can be set further away from the fence which will help hold your work piece

more securely to the table saw surface. (See

Figure #4

below for mounting distances) If your fence is close to

the blade the stock guide can be positioned close to the fence providing clearance from the blade. Once this

is done then securely tighten the clamping knob. This outward radius edge of the stock guide is slightly

higher than the contact surface of the tires and by tightening the stock guide in this position it ensures the

correct amount of spring pressure and travel on your stock.

USING YOUR CLEAR-CUT TS STOCK GUIDES

8.

FIGURE #4

MOUNTING DISTANCE

MINIMUM RECOMENDED DISTANCE OF

TRACK TO OUTSIDE OF FENCE FACE

13/16" (20 MM) TO CLEAR FENCE WHEN

NOT IN USE

0.921

2.000

MAXIMUM STOCK

THICKNESS = MOUNTING

DI 0.921"

TABLE SAW SURFACE