3

INSTALLATION OF APPLIANCE

The installation of this appliance must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1--Latest Edition, or, in Canada, CAN/CGA-B149 Installation Code,

Latest Edition.

This appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70--Latest Edition, or, in Canada,

current CSA Standard C22.1 Canadian Electrical Code, Part 1.

All supply piping, except as noted, should use common National Pipe

Thread (N.P.T.). For all pipe connections use an approved pipe joint

compound resistant to the action of LP gas.

CAUTION:

Warranty is void on Jenn-Air equipment installed other than as

recommended by manufacturer.

This appliance is designed for use with the appliance gas pressure

regulator supplied with this appliance. It must be installed in the gas way

ahead of the gas manifold entrance. It is preset for use with natural gas and

must be converted, as described on page 6, for use with LP gas. (See

figures 10 and 11.)

This appliance is designed to operate at a pressure of 5 inches of water

column on natural gas or, if converted for use with LP gas (propane or

butane), 10 inches water column. Make sure this appliance is supplied with

and adjusted for the type of gas for which it is designed.

This appliance was adjusted at the factory for use with natural gas. If, at any

time, this appliance is to be used with a different type of gas, all of the

conversion adjustments described on pages 5 and 7 must be made by a

qualified service technician before attempting to operate the cooktop on

that gas. Natural gas should be supplied to theappliance pressureregulator

at a line pressure between 6 and 14 inches of water column or, if converted

for LP gas, between 11 and 14 inches.

WARNING:

If the line pressure supplying the appliance pressure

regulator exceeds 14

²

W.C. (any gas), an external regulator must be

installed in the gas line ahead of the appliance regulator to reduce the

pressure to no more than 14

²

W.C. Failure to do this can result in

malfunction and damage to the appliance.

Insure this appliance is adjusted for the type of gas supplied to it and that

the gas supply pressure to the appliance regulator is within the proper

pressure range.

S

If this is a 36

²

wide model, or if it is a 30

²

wide model and no other

appliance is to be installed in the cabinetry below it, proceed as

instructed under paragraph

I

.

S

If this is a 30

²

wide model and a Jenn-Air Model W30XXX or W131

Electric Wall Oven is to be installed in cabinetry below, proceed as

instructed under paragraph

II

.

S

Do not remove protective cap from pipe stub at manifold entrance until

ready to join gas supply piping to appliance.

NOTE:

In Canada, gas utilization codes prohibit use of street elbows. Use

standard pipe elbows and make modifications to these instructions as

necessary.

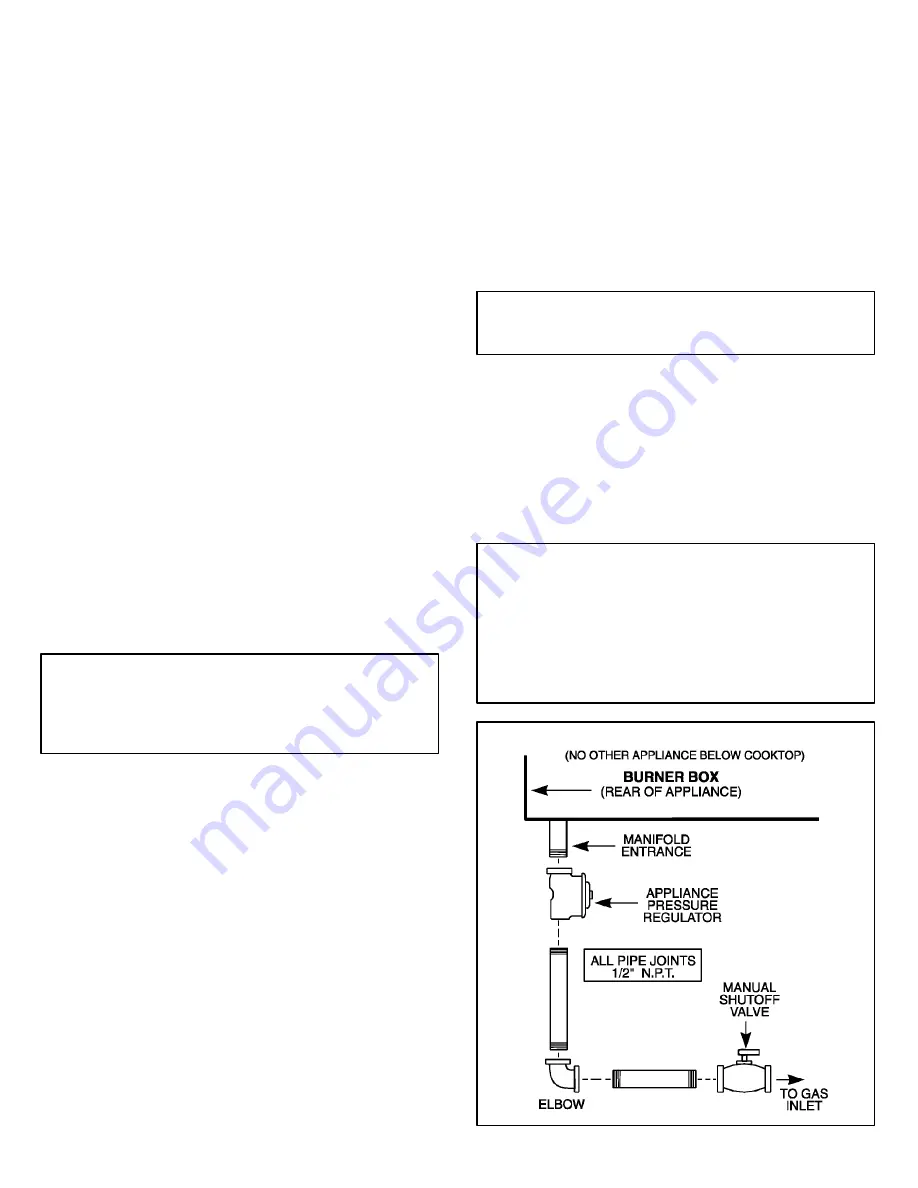

CONNECTING APPLIANCE TO GAS SUPPLY

A TRAINED SERVICEMAN OR GAS APPLIANCE INSTALLER MUST

MAKE THE GAS SUPPLY CONNECTION. Leak testing of the appliance

shall be conducted by the installer according to the instructions

given.

1. IF NO OTHER APPLIANCE IS TO BE INSTALLED BELOW THIS

COOKTOP

Join the appliance pressure regulator supplied with this appliance to the

entrance threads of the Gas Manifold. The appliance regulator is marked

with a directional arrow indicating correct direction of gas flow. Ensure the

appliance regulator is installed with the arrow pointing toward the gas

manifold entrance. Tighten the appliance regulator to 20 to 30 ft-lbs of

torque.

IMPORTANT

Never tighten to more than 35 ft-lbs of torque. Always use an approved

pipe joint compound resistant to the action of LP gas.

Install the appliance in its counter cutout.

Make the gas connection to the inlet of the appliance pressure regulator

with 1/2

²

male pipe threads.

Install a manual shut-off valve in an accessible location in the gas line

ahead of the appliance pressure regulator and external to this appliance for

the purpose of turning on or shutting off gas to the appliance.

Make additional pipe connections as necessary ahead of the shut-off valve

to the gas supply source. Assure all pipe joint connections are gas tight.

IMPORTANT

Apply a non-corrosive leak detection fluid to all joints and fittings in the

gas connection between the supply line shut-off valve and the range.

Include gas fittings and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles appearing around fittings

and connections will indicate a leak. If a leak appears, turn off supply line

gas shut-off valve, tighten connections, turn on the supply line gas shut

off valve, and retest for leaks. Never test for gas leaks with an open

flame.

FIGURE 3

ILLUSTRATIVE GAS SUPPLY PIPING