15

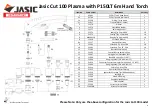

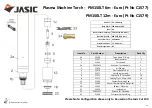

Drag Tip Cutting

Drag tip cutting is the process of dragging the tip of the torch along the workpiece to cut the metal.

This is often the easiest way to cut while minimizing heat input but usually only on cutting currents

of 40amps and below. This technique works best when the material being cut is 5mm or less.

Drag tip cutting does require a

‘

drag

’

cutting tip and you need to ensure that the plasma machines

output amperage is matched to the amperage with the cutting tip.

It can often be helpful to use a non

-

conductive straight edge to help maintain a straight cut.

Drag Shield Cap Cutting

The drag shield cap option allows the same technique to be used but having the cutting tip

insulated (shielded) from the material being cut. Using a drag shield cap allows you to rest the torch

(via the drag cap) on the workpiece while maintaining an optimal 2

-

3mm standoff without touching

the cutting tip to the material for amperages 40amps and above. (When cutting at above 40amps,

touching the tip to the work material will adversely affect your cut quality and consumable life).

When you start to drag cut, you would place the tip/cap of the torch on the workpiece and begin

dragging (moving) the torch across the workpiece.

You should always start with the torch placed at the farthest point from you and then cut by pulling

the torch towards you while making sure to keep the torch upright to the material being cut

throughout the cutting process.

As you are drag cutting ensure you maintain a smooth and consistent travel speed to make a clean,

precise cut.

The main benefits of drag cutting is:

Much easier for the operator because you don't need to maintain a distance between the

cutting tip and the workpiece. You can simply drag the end of the plasma torch along a

template or a straight edge. This process usually ensures a more accurate cut.

Drag cutting produces less spatter and blow back and improves the life of the front end torch

parts.

Best cut quality for material of 5mm or less.

Description of Drag Cutting

DRAG TIP CUTTING

DRAG SHIELD CAP CUTTING

Wilkinson Star Technical