13

Wilkinson Star Technical

General Plasma Cutting Information

Before starting any welding or cutting activity ensure that you have suitable eye protection and

protective clothing. Also take the necessary steps to protect any persons within the welding area.

Notes for cutting operation

Do not touch the hot workpiece with bare hands to avoid burning.

It is recommended not to ignite the arc in the air if not necessary, for it will shorten the lifespan of the electrode and nozzle of the torch.

It is recommended to initiate the cutting from the edge of the workpiece unless penetration is needed.

Ensure spatter comes from the bottom of workpiece while cutting. If spatter comes upwards from the top of workpiece, it indicates that the

workpiece has not been fully cut through. This could be due to not enough power or the cutting torch is moved too fast.

For cutting a round or shaped piece or to meet precise cutting requirement, a stencil board or other tools are needed.

It is recommended to pull the cutting torch while cutting.

Keep the nozzle of the cutting torch upright over the workpiece and check if the arc is moving with the cutting line. Do not bend the cable too

much, step on or press upon the cable to avoid restricting the air flow. The cutting torch may be burned if the air flow is too low. Keep the cutting

cable away from sharp edges.

When the workpiece is nearly cut off, slow down the cutting speed and release the torch trigger to stop cutting.

Check the torch consumables frequently to prolong the life.

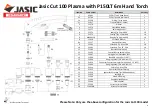

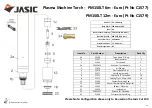

Always ensure the correct consumables are fitted in the torch. Incorrect items may cause damage to the torch or machine.

It is recommended that a torch of maximum length of 6 metres is used. If the torch cable is too long, the performance of this cutting machine

such as arc ignition will possibly be affected due to the fact that the inner resistance of the cable will reduce the output voltage.

•

Please Note:

•

Your air supply must be free of moisture, water, oil or any other contaminants. Excessive water or oil may cause double arcing, excessive

electrode/tip wear or even torch head failure. Contaminants will also cause poor cut quality.

•

When starting the arc, ensure you keep the pilot arc time to a minimum to avoid excessive wear on the cutting tip.

•

Do not overtighten the electrode when fitting a new set of consumables. Over tightening may cause damage to the internal torch head thread

so that the cutting tip will not seat correctly.

•

Only use the supplied or recommended

’

O

’

ring lubricant or grease for your plasma torch head, using the wrong lubricant that cannot

withstand high temperatures could cause damage to the plasma torch head.