14

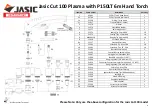

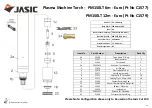

Description of Stand

-

off Cutting

Stand

-

Off Cutting

The stand

-

off cutting technique is the process of holding the tip of the torch

between 3

-

4mm from the workpiece to achieve the optimum cut.

Stand

-

off cutting requires a cutting tip that you need to ensure that the plasma

machines output amperage is matched to the amperage with the tip.

Depending on the application the operator may choose to hold the torch

‘

free hand

’

away

from the plate or could choose to use a stand

-

off guide to help hold the torch away from

the plate at a fixed height, also available are roller guides and

circle cutting guide kits which can be very helpful in creating the cuts you want.

To begin cutting you would place the torch above the work piece of about 3

-

4mm, and

begin drawing the tip across the workpiece.

You should always start with the torch placed at farthest point from you and then cut by

pulling the torch towards you.

Make sure to keep the torch upright to the material being cut throughout the cutting pro-

cess.

As you are cutting ensure you maintain a smooth and consistent travel speed to make a

clean and precise cut.

There are 3 main reasons why plasma machine operators prefer to use the stand

-

off tech-

nique rather than drag tip cutting

It allows for a smoother movement of the torch above the material being cut without

any part of the torch touching the material.

You can comfortably stand the torch while making the contouring process or following

a certain pattern.

Because the cutting tip is not touching the material, this helps to prevent any blow-

back of molten material.

FREE HAND STAND

-

OFF CUTTING

STAND

-

OFF GUIDE CUTTING

Wilkinson Star Technical