38

Darning Stitch

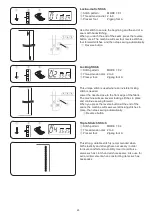

q

Stitch pattern:

MODE 1: 32

w

Thread tension dial: 3 to 6

e

Presser foot:

Automatic buttonhole foot R

q

w

e

r

w

y

u

z

x

c

v

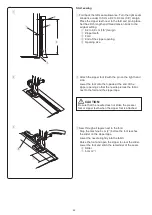

Sewing a shorter darning

To sew a darning shorter than 3/4˝ (2 cm), first stop the

machine after sewing the required length

y

, then press

the reverse button

t

.

The required length

y

has been determined.

Start the machine again and continue sewing until the

machine stops automatically.

t

Reverse button

y

Required length

u

Starting point

Sewing a same-sized darning

Simply start the machine to sew another darning at the

same size.

Adjusting the evenness of darning

Correct the evenness of the darning as follows:

“d5” is the default setting value.

When the right side of the darn is lower than the left side,

press the “+” sign on the stitch length adjusting key

q

to

set the value to “d6” to “d9”, and make the darn even.

When the left side of the darn is lower than the right side,

press the “–” sign on the stitch length adjusting key

q

to

set the value to “d1” to “d4”, and make the darn even.

q

Stitch length adjusting key

Starting to sew

z

Attach the automatic buttonhole foot R and pull the

button holder

q

all the way out.

Draw the needle thread to the left through the hole of

foot.

q

Button holder

x

Place the fabric under the foot, and lower the needle

at the starting point

w

. Then lower the foot.

w

Starting point

c

Start the machine. The machine will sew locking

stitch, 16 rows of darning, locking stitch again and

stop automatically.

v

Turn the fabric and repeat sewing in different direction.

e

3/4˝ (2 cm)

r

9/32˝ (0.7 cm)

t

4

w

e

q

q

NOTE:

To reset the size of the darning, select the other stitch

pattern and reselect the darning stitch.

Summary of Contents for M7200

Page 1: ...Instruction Book...

Page 2: ......

Page 62: ...60 Stitch Chart MODE 1 MODE 2...

Page 63: ...61 Stitch Chart MODE A MODE...

Page 64: ...812 800 113 EN...