Setup

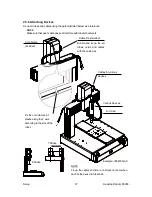

Desktop Robot JR3000

TCP-

∆

Z

After changing tools etc., if the tool height is different from the registered tool center point position,

enter the Z-direction difference to TCP-

∆

Z.

NOTE: When adding a new program, the values of the default all program common settings

(customizing data) are entered as program data default values.

Additionally, when using the additional function data [Tool Data], you can change tool data at intervals

between specific points. For example, it is possible to change the registered tool mass settings for only

the period of time it is gripping something.

MENU [Individual Program Settings]

[Tool Data]

NOTE: When the bottommost item shown is highlighted, press the CURSOR key to display

the other settable items for that point.

[Program]

Æ

[Individual Program Settings]

Æ

[Tool/Workpiece]

Æ

[Tool Data]

7.2 4-Axis Specifications: Tool Data

The following settings are in [Tool Data]:

•

Tool Mass (mass affecting the Y axis)

•

TCP-X: The X direction distance from the R axis center to the tool tip.

•

TCP-Y: The Y direction distance from the R axis center to the tool tip.

•

TCP-

∆

Z: The Z direction distance from the tool tip height during teaching to the current tool tip

height.

The offset value for the offset from the tool tip is referred to as the tool center point (TCP).

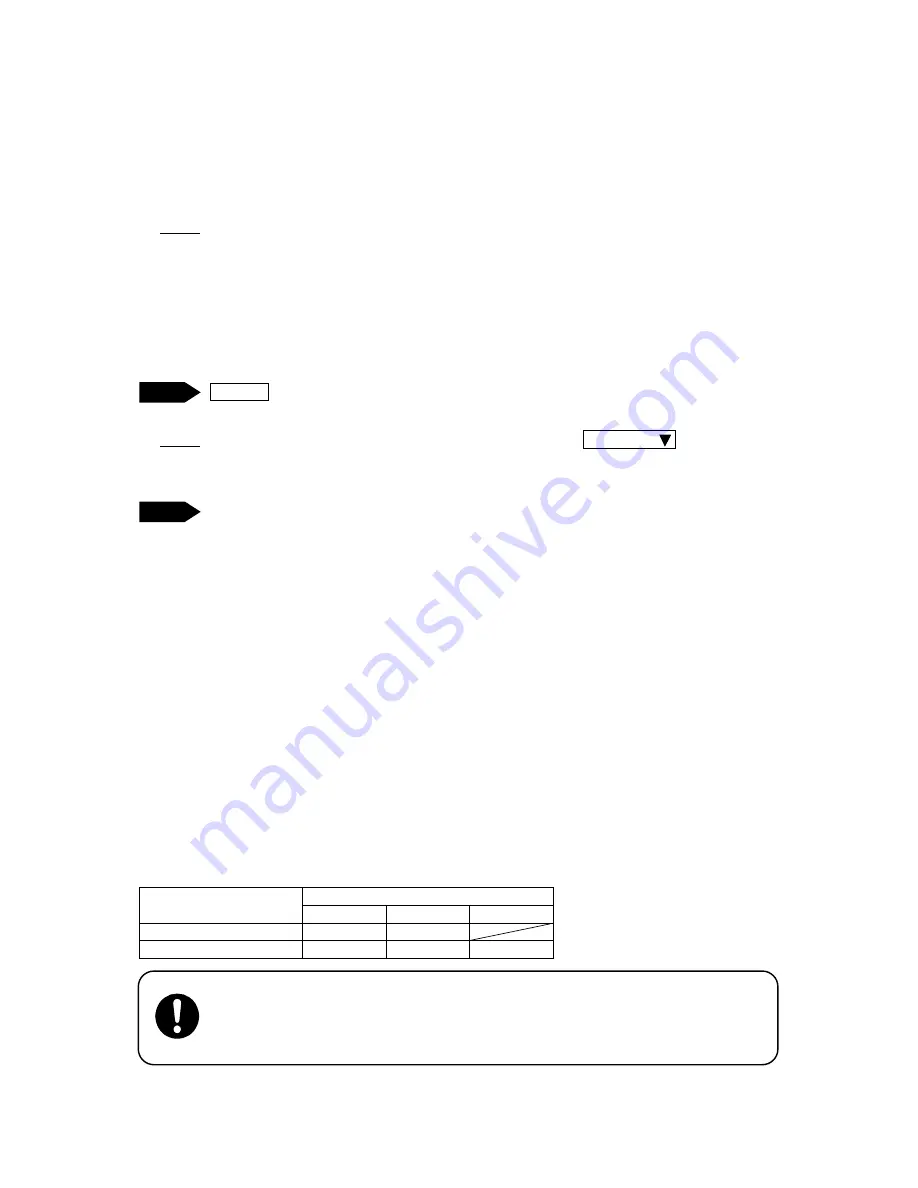

Tool Mass

[Tool Mass] refers to the total mass of the tool and of the object which the tool is holding. Make sure

this mass is equal to or lower than the registered mass. The settings are as follows:

Tool Mass

1

2

3

JR3200

1 kg

3.5 kg

JR3300, JR3400

1 kg

4 kg

7 kg

TP

PC

Caution

If the tool mass is heavier than the registered settings, a position

error may occur.

41