29

2.0 Service

2.12 End of the Year Service(Continued)

5.

Torque lug-nuts (Section 2.4).

6.

Make sure that the tires are properly inflated.

7.

Remove all grain from inside the grain tanks.

8.

Clean out the Conveyor at the end of every season (Section 1.8).

9.

Tension and track the conveyor belt. (Section 2.7).

10.

Check the Speed Tender periodically for cracks in welds and for other structural damage. Have cracked welds fixed immediately.

NOTE: Failure to have cracked welds fixed immediately could result in extensive damage to

The Speed Tender and greatly reduce its life.

11.

Check hydraulic hoses for wear and replace if needed.

12.

Make sure that the conveyor hopper guard is in place.

13.

Remove battery from the Speed Tender and place in a cool dry place.

NOTE: Attaching a trickle charger to the battery will help ensure a long life for your battery.

IMPORTANT: Be sure to disconnect the scales from the battery before charging.

14.

Change hydraulic oil filter element with either a NAPA 155Z or a FRAM P1654A Filter.

15.

Top off hydraulic oil tank with good quality hydraulic AW 32 oil.

NOTE: If the Hydraulic Oil appears to be “Milky” in color it should be changed immediately. Otherwise, the Hydraulic

Oil should be changed every 2-3 years. If the environment is extremely dusty or dirty the Hydraulic Oil should be

changed more often.

15.

Check motor oil level. See Engine operator’s manual for details on oil levels, oil types, and service intervals.

16.

Retract all hydraulic cylinders to prevent the piston rods from rusting.

17.

Touch-up spots where paint has been worn away (use good quality primer paint - especially before

applying graphite paint to the inside of the grain tank).

2.13 Removing From Storage

1.

Grease the conveyor bearings. Use only two pumps of grease per bearing

NOTE: Over lubrication of these bearings will result in premature failure.

NOTE: The conveyor has four bearings that need greased (two at each end). The auger is equipped with one bearing

(at Hopper end) (See section 2.1).

2.

Grease pivot points on boom arm.

3.

Torque lug-nuts (Section 2.4).

4.

Make sure that the tires are properly inflated.

5.

Check your belt for proper tracking every 10 hours of use and before every season. For steps to properly track your belt (Section 2.7).

6.

Check oil level.

7.

Inspect for hydraulic oil leaks and repair as appropriate.

8.

Check all hoses, fittings, bolts, and hardware to make sure that they are secure and properly tightened.

9.

Check engine oil level. See Engine operator’s manual for details on oil levels, oil types, and service

intervals.

10.

Check Speed Tender lights before each time you tow.

11.

Make sure that the conveyor hopper guard is in place.

12.

Reattach battery and check to make sure that it is fully charged.

IMPORTANT: Be sure to disconnect the scales from the battery before charging.

Summary of Contents for 510-ST

Page 3: ...3...

Page 9: ...9 Decals 4 11 13 7 12 14 9 10 11 16 15 17...

Page 33: ...33...

Page 55: ...55...

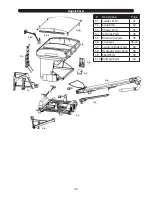

Page 57: ...57 5 0 Parts Includes 6 Dia Clamp with M10 X 1 1 2 L Bolt 5 6 7 8 9...