23

2.0 Service

2.8 Adjusting Conveyer Belt Tracking

1.

Loosen (Do Not Remove) the 4 bolts on the two bearing mounting plates located at the collapsible hopper end of the

conveyor (Figure 2.5).

NOTE: Only adjust conveyor in normal position, do not adjust in self-fill position.

2.

Operate the conveyor at a slow speed.

CAUTION: Keep hands and clothing away from moving parts.

3.

Loosen jam nut on adjustment bolt (Figure 2.5).

4.

Tighten the adjustment bolt slowly until belt is running in the center of the pulley.

NOTE: Do not loosen the Adjustment bolt.

5.

Tighten all bolts on bearing mounting plate, and adjustment bolts jam nuts.

6.

Repeat at discharge end.

7.

When belt is running in center of the pulley on both ends of conveyor, allow the Speed Tender to run for 10 min, and

recheck belt for proper tracking.

Conveyer

Clean-out Door

Figure 2.4

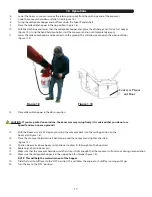

Remove

Remove

Loosen these

bolts when adjusting belt

tension. Typical each side.

Jam Nut

Adjustment Bolt

Bearing Mounting

Plate

Discharge Pan

Loosen these

bolts when adjusting belt

tension. Typical each side.

Jam Nut

Adjustment Bolt

Bearing Mounting

Plate

Figure 2.5

Jam Nut

A

B

Measurments A & B need to be the same.

Summary of Contents for 510-ST

Page 3: ...3...

Page 9: ...9 Decals 4 11 13 7 12 14 9 10 11 16 15 17...

Page 33: ...33...

Page 55: ...55...

Page 57: ...57 5 0 Parts Includes 6 Dia Clamp with M10 X 1 1 2 L Bolt 5 6 7 8 9...