en-48

JACOBSEN TR3

SAFETY, OPERATORS & MAINTENANCE MANUAL

9

ADJUSTMENTS

CUTTING UNITS 47114, 47115, 47116

9.9

REEL-TO-BEDKNIFE (Pre-Adjustment

Check)

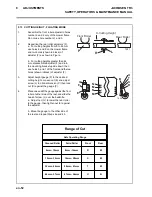

1.

Check the reel for end play or radial play.

If there is any abnormal movement of the

reel, up and down or side to side, adjust or

replace components as needed.

2.

Inspect the blades and bedknife.

a. The blades should not have bends or

nicks. The leading edge of the blades

must be sharp, free of burrs.

b. The bedknife and bedknife backing

must be securely fastened. The bedknife

must be straight and sharp.

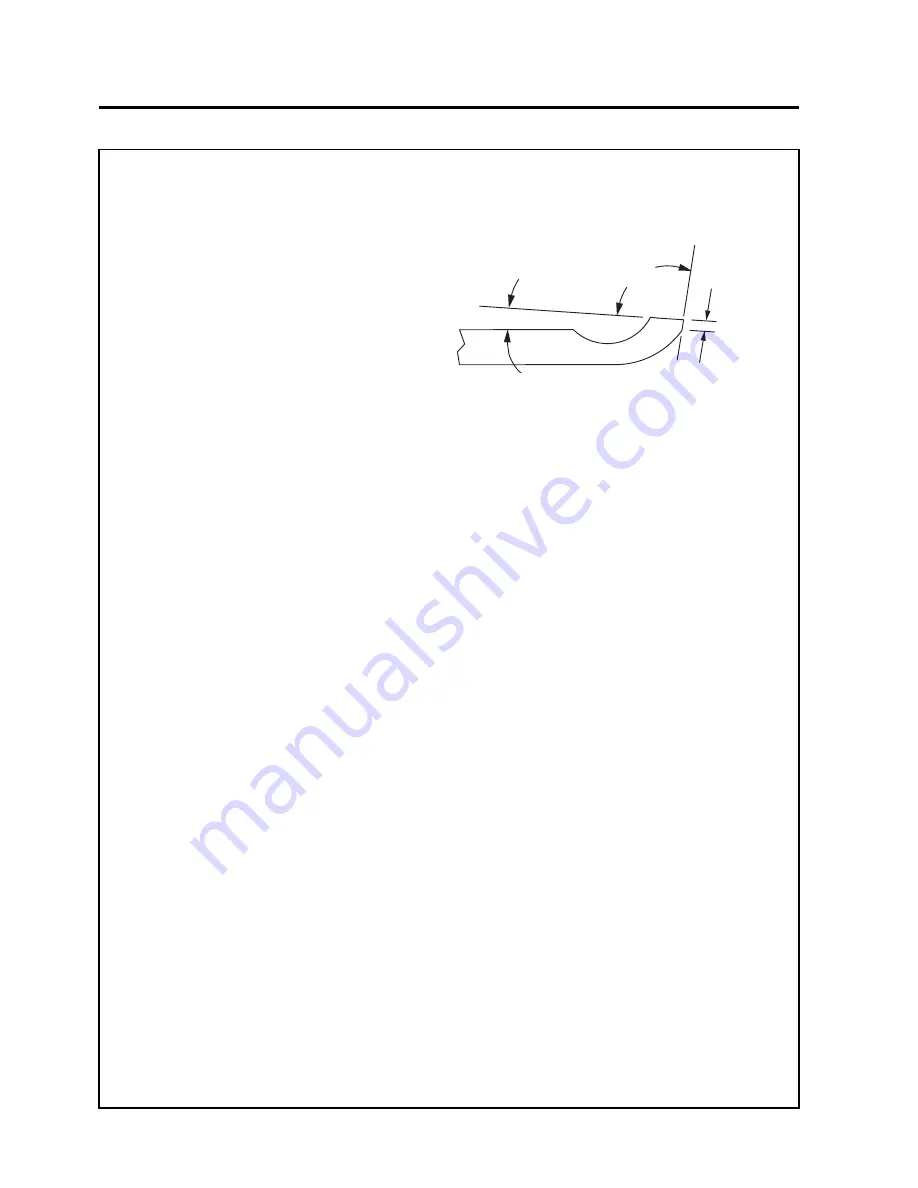

c.

A flat surface of approximately 4 mm

should be maintained across the face of

the bedknife.

3.

If wear or damage is beyond the point

where the reel or bedknife can be corrected

by the lapping process, they must be re-

ground or replaced.

4.

Proper reel to bedknife adjustment is

critical. A gap of 0,025 to 0,05 mm must be

maintained across the entire length of the

reel and bedknife.

a. A reel that is not parallel to the

bedknife will wear conical in shape.

b. A reel set too tight will lose its sharp

edges prematurely and may result in

wavy wear pattern in the bedknife.

5.

Grass conditions will also affect the

adjustment.

a. Dry, sparse conditions will require a

wider gap to prevent heat buildup and

damage to the reel and bedknife.

b. When cutting for high quality grass

with a good moisture content, a closer

clearance (near zero) provides a better

cut and also increases the life of the reel

and bedknife.

5¡-6¡

93¡

TK14

Summary of Contents for TR3 EJ Series

Page 2: ...2010 Ransomes Jacobsen Limited All Rights Reserved...

Page 33: ...en 33 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 7 OPERATION...

Page 35: ...en 35 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 8 MAINTENANCE LUBRICATION...

Page 73: ...en 73 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 11 TROUBLESHOOTING...

Page 74: ...en 74 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 12 1 HYDRAULIC CIRCUIT 12 SCHEMATICS...

Page 84: ......

Page 85: ......