en-3

JACOBSEN TR3

SAFETY, OPERATORS & MAINTENANCE MANUAL

1

CONTENTS

CONTENTS

PAGE

CONTENTS

PAGE

2

INTRODUCTION

2.2 PRODUCT

IDENTIFICATION ...................................... 4

2.1 IMPORTANT................................................................. 4

2.3

GUIDELINES FOR THE DISPOSAL

OF PRODUCTS ........................................................... 4

3

SAFETY INSTRUCTIONS

3.1

OPERATING INSTRUCTIONS..................................... 6

3.2

SAFETY SIGNS............................................................ 6

3.3

STARTING THE ENGINE............................................. 6

3.4

DRIVING THE MACHINE ............................................. 6

3.5

TRANSPORTING ......................................................... 6

3.6

LEAVING THE DRIVING POSITION............................ 7

3.7

SLOPES ....................................................................... 7

3.8

BLOCKED CUTTING UNITS ....................................... 7

3.9 ADJUSTMENTS,

LUBRICATION

AND MAINTENANCE................................................... 7

4

SPECIFICATIONS

4.1

ENGINE SPECIFICATION ........................................... 9

4.2

MACHINE SPECIFICATION ........................................ 9

4.3

DIMENSIONS ............................................................... 9

4.4

VIBRATION LEVEL.................................................... 10

4.5

SLOPES ..................................................................... 10

4.6

CUTTING UNIT SPECIFICATION.............................. 11

4.7

RECOMMENDED LUBRICANTS............................... 11

4.8

CUTTING PERFORMANCE (AREA) ......................... 11

4.9

CONFORMITY CERTIFICATES................................. 12

5

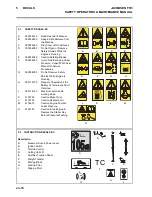

DECALS

5.2

INSTRUCTION DECALS EC...................................... 16

5.1

SAFETY DECALS EC ................................................ 16

5.3

SAFETY DECALS USA ............................................. 17

5.4

INSTRUCTION DECALS USA ................................... 17

6

CONTROLS

6.1

INSTRUMENT PANEL ............................................... 18

6.1A

STARTER KEY SWITCH .......................................... 19

6.1B

WORKING LIGHT SWITCH ....................................... 19

6.1C

PARKING BRAKES ................................................... 19

6.1D

CUTTING UNIT SWITCH ........................................... 19

6.1E

WEIGHT TRANSFER SWITCH.................................. 20

6.1F

BLOCKED HYDRAULIC FILTER INDICATOR

LAMP.......................................................................... 20

6.1G

CHARGE WARNING LAMP....................................... 20

6.1H

ENGINE COOLANT TEMPERATURE

WARNING LAMP ....................................................... 20

6.1J

ENGINE OIL PRESSURE WARNING LAMP............. 20

6.1K

CONTROL MODULE FAULT WARNING LAMP ....... 21

6.1L

ENGINE PREHEAT INDICATOR LAMP.................... 21

6.1M

THROTTLE CONTROL LEVER ................................ 21

6.1N

JOYSTICK UNIT LIFT/LOWER CONTROL............... 21

6.1P

MULTI FUNCTION GAUGE ....................................... 22

6.2

TRACTION FOOT PEDAL ........................................ 23

6.3

STEERING TILT CONTROL ...................................... 23

6.4

POWER OUTLET ....................................................... 23

6.5

PARKING BRAKE RELEASE VALVE....................... 24

6.6

TRANSPORT LATCHES............................................ 24

7

OPERATION

7.1

DAILY INSPECTION .................................................. 25

7.2

OPERATOR PRESENCE AND SAFETY

INTERLOCK ............................................................... 26

7.3

OPERATING PROCEDURE....................................... 27

7.4

FITTING THE CUTTING UNITS TO THE MACHINE . 28

7.5

STARTING THE ENGINE .......................................... 29

7.6

DRIVING .................................................................... 29

7.7

MOWING .................................................................... 29

7.8

TO STOP THE ENGINE ............................................. 29

7.9

MOWING ON SLOPES .............................................. 30

8

MAINTENANCE & LUBRICATION

8.1

MAINTENANCE & LUBRICATION CHART .............. 34

8.2

CUTTING UNIT LMAC194/195/196/197

LUBRICATION ........................................................... 36

8.3

CUTTING UNITS 47114, 47115, 47116

LUBRICATION ........................................................... 37

8.4

ENGINE LUBRICATION ............................................ 38

8.5

ENGINE: FAN BELT .................................................. 38

8.6

ENGINE COOLANT ................................................... 39

8.7

HYDRAULIC SYSTEM............................................... 40

8.8

HYDRAULIC TEST PORTS ....................................... 41

8.9

FUEL SYSTEM........................................................... 42

8.11

BATTERY................................................................... 43

8.10

AIR CLEANER ........................................................... 43

8.12

MACHINE MAINTENANCE ....................................... 44

8.13

FREEWHEEL CONTROL .......................................... 44

9

ADJUSTMENTS

9.1

TRACTION CONTROL PEDAL ................................. 45

9.2

WEIGHT TRANSFER ADJUSTMENT ....................... 45

9.3

HEIGHT OF CUT........................................................ 46

9.4

TO SET REAR ROLL................................................. 46

9.5

TO SET HEIGHT OF CUT.......................................... 46

9.6

REEL TO BEDKNIFE ADJUSTMENT ....................... 47

9.7

REEL BEARINGS ...................................................... 47

9.8

FRONT AND REAR ROLL BEARINGS..................... 47

9.9

REEL-TO-BEDKNIFE (PRE-ADJUSTMENT

CHECK)...................................................................... 48

9.10

REEL-TO-BEDKNIFE ADJUSTMENT ...................... 49

9.11

CUTTING MODES...................................................... 50

9.12

CUTTING HEIGHT - FIXED MODE............................ 51

9.13

CUTTING HEIGHT - FLOATING MODE.................... 52

9.14

SPEED LIMITER ........................................................ 53

9.15

SEAT (MILSCO CE-200) ........................................... 53

9.16

SEAT (MICHIGAN V-5300) ....................................... 54

9.17

GENERAL INSTRUCTIONS FOR

GRAMMER SEATS.................................................... 55

9.18

SEAT (GRAMMER MSG85)....................................... 57

9.19

AIR SUSPENSION SEAT

(GRAMMER MSG75 -521) ......................................... 58

9.19.1

WEIGHT ADJUSTMENT............................................ 58

9.19.2

FORE/AFT ADJUSTMENT ........................................ 58

9.19.4

SEAT HEATER .......................................................... 59

9.19.5

LUMBAR SUPPORT.................................................. 59

9.19.3

BACKREST EXTENSION .......................................... 59

9.19.6

ARMRESTS................................................................ 60

9.19.7

ARMREST ADJUSTMENT ........................................ 60

9.19.8

BACKREST ADJUSTMENT ...................................... 60

9.19.9

MAINTENANCE ......................................................... 61

10

ACCESSORIES

10.1

BACKLAPPING KIT (LMAC161).............................. 62

10.2

OPS FRAME (LMAC164).......................................... 63

10.3

TRANSPORT LATCH KIT (LMAC174)..................... 63

10.4

WORKING LAMP KIT (LMAC163) ........................... 63

10.5

GRASS BOX KIT (LMAC182 ).................................. 63

10.6

GRASS BOX KIT (LMAC193 ).................................. 63

11

TROUBLESHOOTING

11.1

GENERAL .................................................................. 64

11.2

QUALITY OF CUT TROUBLESHOOTING ................ 65

12

SCHEMATICS

12.1

HYDRAULIC CIRCUIT ............................................... 74

12.2

ELECTRICAL CIRCUIT INSTRUMENT..................... 76

12.3

ELECTRICAL CIRCUIT MAIN ................................... 78

12.4

ELECTRICAL CIRCUIT FUSES AND RELAYS ........ 80

13

TORQUES

13.1

TORQUES .................................................................. 82

14

GUARANTEE / SALES & SERVICE.......................... 83

Summary of Contents for TR3 EJ Series

Page 2: ...2010 Ransomes Jacobsen Limited All Rights Reserved...

Page 33: ...en 33 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 7 OPERATION...

Page 35: ...en 35 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 8 MAINTENANCE LUBRICATION...

Page 73: ...en 73 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 11 TROUBLESHOOTING...

Page 74: ...en 74 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 12 1 HYDRAULIC CIRCUIT 12 SCHEMATICS...

Page 84: ......

Page 85: ......