en-65

JACOBSEN TR3

SAFETY, OPERATORS & MAINTENANCE MANUAL

11

TROUBLESHOOTING

11.2

QUALITY OF CUT TROUBLESHOOTING

It is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs.

An area should be available where “test cuts” can be made. This area should provide known and consistent turf

conditions to allow accurate evaluation of the mower’s performance.

Another “test cut” should be performed after the completion of the repairs and/or adjustments to verify the

mower’s performance.

Before performing a “test cut” to diagnose cut appearance and mower performance, the following items should

be verified to ensure an accurate “test cut.”

1.

Mowing (Ground) Speed.

2.

Reel Bearing Condition and Pre-Load (End Play) Adjustment.

3.

Reel and Bedknife Sharpness.

4.

Bedknife Alignment to Reel.

5.

Reel-to-Bedknife Contact.

6.

Height-of-Cut (HOC).

7.

Roller and Roller Bearing Condition.

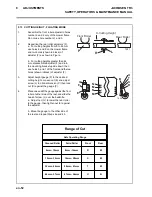

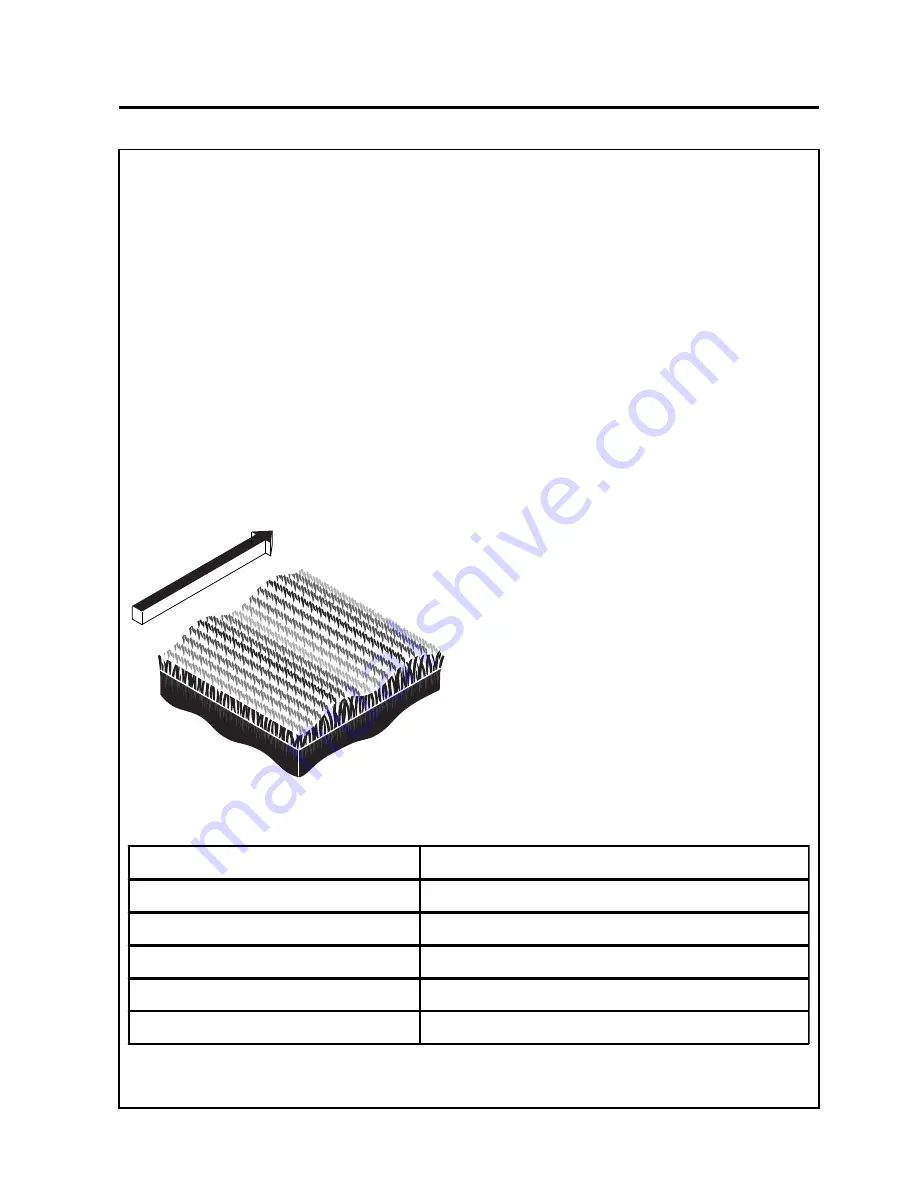

11.2.1 WASHBOARDING

NOTE: Arrow indicates direction of travel.

Washboarding is a cyclical pattern of varying cutting

heights, resulting in a wave-like cut appearance. In

most cases, the wave tip-to-tip distance is

approximately 6—8 in. (15—20 cm). Colour

variation (light-to-dark) may also be noticed.This

condition is usually caused by a rocking motion in

the cutting unit(s). This condition is found mostly on

mowers with multiple (suspended) cutting units, but

other causes can produce the same

result.Washboarding may also be caused by

variations in the turf.

Probable Cause

Remedy

Mowing (ground) speed is too fast.

Reduce mowing (ground) speed.

Grass build-up on roller.

Clean the roller and use scrapers or brushes.

Roller is out of round.

Replace roller.

Mowing in the same direction.

Change mowing direction regularly.

Use of a groomer on cleanup pass.

Groomers should be used only in a straight line.

Summary of Contents for TR3 EJ Series

Page 2: ...2010 Ransomes Jacobsen Limited All Rights Reserved...

Page 33: ...en 33 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 7 OPERATION...

Page 35: ...en 35 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 8 MAINTENANCE LUBRICATION...

Page 73: ...en 73 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 11 TROUBLESHOOTING...

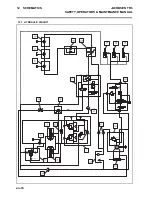

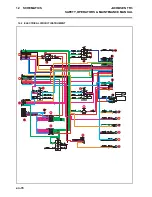

Page 74: ...en 74 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 12 1 HYDRAULIC CIRCUIT 12 SCHEMATICS...

Page 84: ......

Page 85: ......